The Engineering Mind podcast – Testing and simulation

Recently, our CEO, Florent Mathieu, had the honor of joining Jousef Murad to discuss testing & simulation on his podcast, The Engineered Mind. In this conversation, Florent dives into the heart of what makes EikoSim a game-changer in the realm of structural simulation. From the intricate details of test preparation and instrumentation to the invaluable…

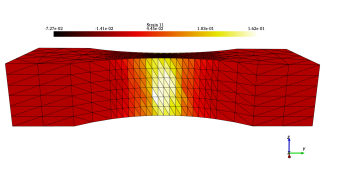

Calibration of material parameters from a single test: workflow

By Florent Mathieu, CEO of EikoSim. Images and data – credits IRT St Exupéry How can you perform calibration of several material parameters with a single test? Here’s a guide. In a previous article, we explored the possibilities offered by lattice structures and showed how it is possible to measure these complex kinematics using Digital…

Digital Image Correlation – The basics

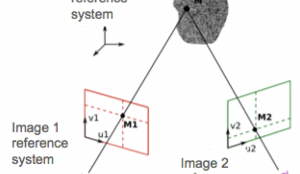

By Florent Mathieu, CEO of EikoSim What is digital image correlation? The Digital Image Correlation (DIC) technique is a non-contact, full-field measurement approach that enables the assessment of the deformation and motion of objects. This is achieved by comparing digital images of the object before and after deformation. DIC measurement is a technique used to…

VVUQ references & resources for solid mechanics & aerospace

By Florent Mathieu, CEO of EikoSim After several occasions where I’ve been given advice to consult specific documents in the field of validation testing and VVUQ (Verification, Validation, and Uncertainty Quantification), I’ve decided to write a blog about this. Here is a more detailed list of important papers, books or websites that I found along…

What is VVUQ (Verification, Validation, and Uncertainty Quantification)?

By Florent Mathieu, CEO of EikoSim In the world of scientific simulations, ensuring accuracy, reliability, and credibility is of utmost importance. To achieve this, scientists and engineers employ a rigorous process called Verification, Validation, and Uncertainty Quantification (VVUQ). This blog article explores what VVUQ entails, its applications across various software product domains, and its role…

How to make a speckle pattern suitable for Digital Image Correlation?

Context: Speckle patterns & digital image correlation The principle of image correlation is based on tracking information from a so-called “reference” image in the following images, often called “deformed images.” When using digital image correlation (DIC), speckle patterns are created on the surface of a specimen to address uniqueness concerns. As a result, the accuracy…

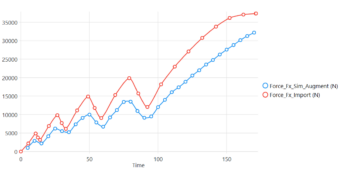

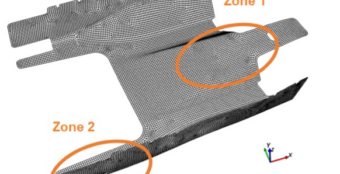

Integrating multi-camera DIC at MBDA

As part of its increasing competence in cutting-edge measurement techniques, MBDA has launched a process of testing and internal auditing of measurement resources by multi-camera DIC (Digital Image Correlation). After testing these measurement tools on coupon-type test campaigns, a new stage has been launched with the testing of this technology on more complex structures using multi-camera systems. Compressive…

Crash-test and image correlation: how to measure seat deformations and follow the dummy’s movements

Crash tests are crucial in developing and certifying products, especially for the automotive, aeronautical, and railway industries. These tests simulate collision or impact scenarios in order to evaluate the resistance and safety of products. Among the equipment used to perform these tests is the reverse catapult, which is a device that projects an object, in…

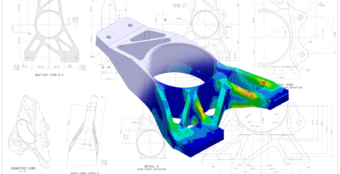

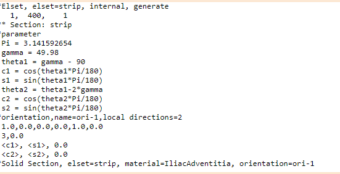

Simulation correlation with Abaqus: how far we’ve come in linking a solver to our software environment

Need to perform a correlation between an Abaqus simulation model and measurements automatically? Whether it is by developing a Python script, actually using the C++ API or developing our parsers, we have experimented a lot with reading and writing formats related to this solver, whether it is to correlate displacement or deformation fields or simply…

Mechanical regularization in EikoTwin DIC

In EikoTwin DIC, the measurement of displacement fields is performed on the simulation mesh. However, as this mathematical problem is by nature ill-posed, a mechanical regularization parameter allows the user to add mechanical conditions to the field measurements. Contrary to most digital image correlation software, at EikoSim, we have chosen to use a mechanical “filter”.…