EikoTwin DIC

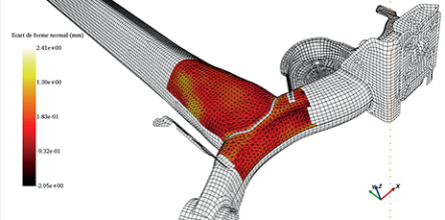

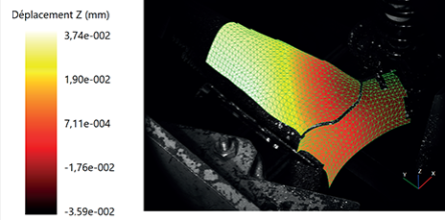

EikoTwin DIC is a digital image correlation (DIC) software program and system that links measurements and numerical simulations.

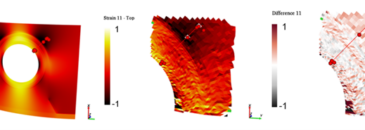

It uses a patented Digital Image Correlation technology to provide automatic test-simulation comparison.

It allows the efficient determination of model errors and the identification and resolution of error sources. EikoTwin is the only global FE-based digital image correlation software package built with simulation validation in mind.

EikoSim's engineering partners and customers

EikoTwin DIC is available on the Altair Partner Alliance Platform

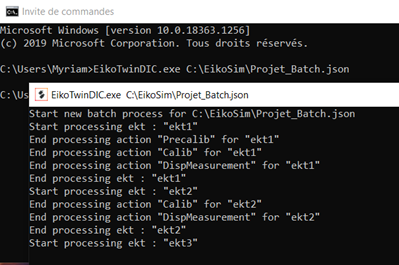

"Batch mode" plug-in

- This tool multiplies the power of EikoTwin DIC by allowing batch processing of image series.

- Process all your measurements in a batch process and increase the value you get from EikoTwin DIC.

Feature demos

FE compatibility

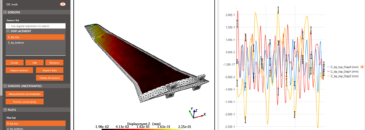

Multi-camera measurements

- Use all of your cameras within the same reference system - and the right one

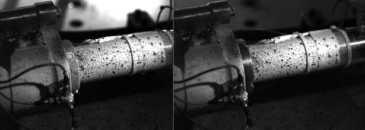

Measure close to the edge

- Obtain a measurement up until the edge of your specimen thanks to mesh-based DIC

Testimonials

Applications and tutorials

Modal analysis validation – in practice

In a recent post, we mentioned how DIC can be used for modal analysis validation by comparing the measured field with a finite element simulation. A practical exercise was proposed to us by INTES: how to export results to a simulation pre-post, in this case that of the PERMAS software? In this case, we have…

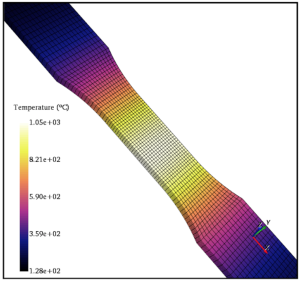

Building simulation credibility: the validation of Ariane 6’s Dual Launch Structure

Ensuring the credibility of simulation models is a concern in all fields of engineering. In aerospace engineering, structural qualification is a crucial step in ensuring that critical components are capable of withstanding the most severe operational conditions. This process is essential to ensure the safety and reliability of systems during missions. This article focuses on…

Modal analysis: how can Digital Image Correlation (DIC) help?

Modal analysis is a key technique used in engineering to understand the vibratory behavior of mechanical structures. It enables us to determine the natural frequencies and modal shapes of a structure, which are crucial in ensuring that it does not resonate dangerously under specific operating conditions. Traditionally, this analysis has relied on the use of…

Crash-test and image correlation: how to measure seat deformations and follow the dummy’s movements

Crash tests are crucial in developing and certifying products, especially for the automotive, aeronautical, and railway industries. These tests simulate collision or impact scenarios in order to evaluate the resistance and safety of products. Among the equipment used to perform these tests is the reverse catapult, which is a device that projects an object, in…

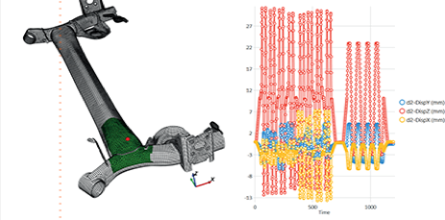

Digital Image Correlation (DIC) for vibration analysis

Digital Image Correlation (or DIC) is well-known for its static applications, but under the right circumstances, it is equally applicable to vibration testing. Here is an industrial example at Safran. As part of the development of increasingly high-performance aircraft actuators, Safran Landing Systems (SLS) must ensure the integrity of its systems during commissioning. With this…

How ArianeGroup improves simulation credibility with EikoTwin and DIC

Simulation credibility is a key aspect of the Virtual Testing concept. As the European leader in space launchers, Ariane Group participates with EikoSim in multiple Research and Development projects, including a RAPID R&D project (“MUTATION”) funded by the Direction Générale de l’Armement. This project aims at developing an industrial platform for test-simulation dialogue to meet…

98-100 AVENUE ARISTIDE BRIAND

92120 MONTROUGE

FRANCE