Digital image correlation for crack measurement

In the context of crack propagation tests on composite material, EikoTwin image correlation solutions were used to meet a customer’s need. A post-processing script, exploiting the measurement data from EikoTwin DIC, was developed by EikoSim to bring satisfaction to the customer with a tailor-made solution. This work is part of Paul Nicolino’s engineering internship at…

Sources of measurement errors with digital image correlation

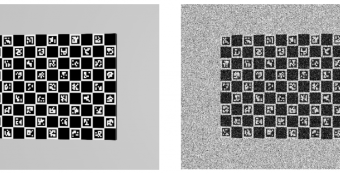

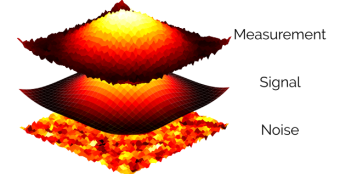

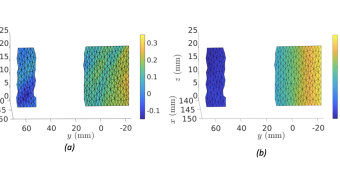

In digital image correlation as in any measurement process, errors affect measured data. The characteristic of this method lies in the direct dependency between the test and the measurement error [1,2,3]. Indeed, errors need to be estimated for every new test. These errors can be classified in two categories: the bias corresponding to systematic errors…

Camera calibration: principles and procedures

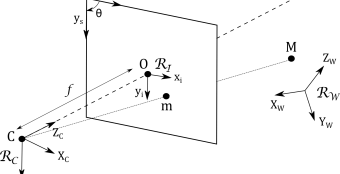

Using a multi-camera system for metrology and accurate measurements requires the calibration of the pixel coordinates of these cameras. They can be represented mathematically by a projection model in the form of a matrix, allowing the passage of the position of 3D points to their projection in 2D image space. The process of estimating the…

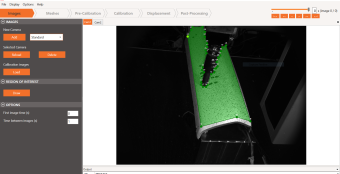

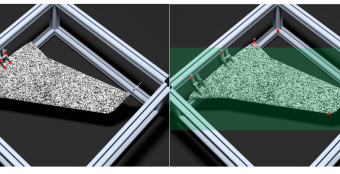

Technical functionality: selection of the measurement mesh

On EikoTwin DIC, the measurements are directly expressed on the simulation mesh. In order to choose which areas of interest for the test are visible to the camera(s), the so-called measurement mesh must first be selected. Indeed, this mesh will be the one where the results will be calculated. It is, therefore, essential to select…

Measurement errors and digital image correlation

By Pierre Baudoin, R&D engineer at EikoSim When conducting a test campaign instrumented by digital image correlation, it must be possible to determine the characteristic measurement error for the quantities of interest studied (measured displacement or strain). This analysis is essential to know whether the measurement made is indeed the desired “signal” and not the…

What are good Digital Image Correlation test practices?

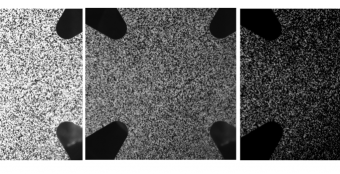

Importance of a good implementation of digital image correlation tests When performing a test by using Digital Image Correlation (DIC), many parameters must be taken into account: brightness, speckle pattern, camera placement. All these steps are essential to achieve the best possible images, in order to get the maximum information from them. Indeed, neglecting one…

Hybrid calibration: a robust alternative to self-calibration

Introduction This article is written as a complement to the article on good calibration practices recently published on our website. In general, it is very often possible to calibrate the camera system in EikoTwin DIC thanks to the knowledge of the geometry of the part, and of the correspondence between points of the model and…

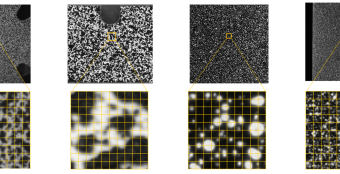

Speckle pattern size: how to calculate it for your DIC test?

In a previous article, we discussed how to choose the size of the speckle pattern for your experiment. We introduced the necessary parameters to control in order to optimize the size of your speckle for each of your tests. As mentioned, although the quality of a speckle pattern can only be analysed with respect to…

Mastering self-calibration of cameras with EikoTwin DIC

To provide accurate Digital Image Correlation (DIC) results, the EikoTwin DIC software must first calibrate the camera system. The use of the part under study as a reference allows a self-calibration of the cameras, specific to EikoTwin DIC. This is made using images of the structure in its reference state (unloaded). Using these images, the…

High-temperature tests for ceramic matrix composites

As a new member of EikoSim team, I was offered the opportunity to present an overlook of my thesis work dealing with high-temperature experiments for SiC/SiC composites, which was carried out in LMT under the supervision of F. Hild and in collaboration with Safran Ceramics under the supervision of V. Herb and B. Lacombe. Credits…

- « Previous

- 1

- 2

- 3

- Next »