Crash-test and image correlation: how to measure seat deformations and follow the dummy’s movements

Crash tests are crucial in developing and certifying products, especially for the automotive, aeronautical, and railway industries. These tests simulate collision or impact scenarios in order to evaluate the resistance and safety of products. Among the equipment used to perform these tests is the reverse catapult, which is a device that projects an object, in…

Digital Image Correlation (DIC) for vibration analysis

Digital Image Correlation (or DIC) is well-known for its static applications, but under the right circumstances, it is equally applicable to vibration testing. Here is an industrial example at Safran. As part of the development of increasingly high-performance aircraft actuators, Safran Landing Systems (SLS) must ensure the integrity of its systems during commissioning. With this…

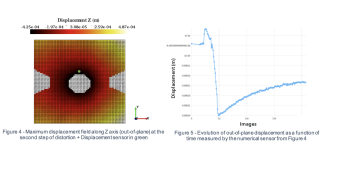

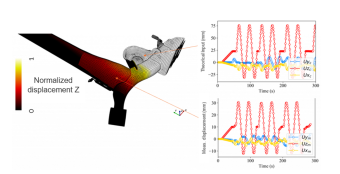

Digital image correlation for automotive structures

Context In the context of monitoring large-scale production of automotive parts, many parts are subjected to repeated tests to ensure their integrity once they are put into service. Thus, the test that we address in this paper is dedicated to the “gust of wind” tests of an opening structure (see Figure 1). Loading tests on…

EikoTwin DIC and the measurement of small strains

Innovation in the automotive industry Innovation is at the heart of the automotive industry: autonomous vehicles, shared mobility, advanced equipment, etc. In order to reinvent themselves and remain competitive, it is necessary for automotive industries to innovate and develop new technologies. It is therefore essential for these companies to perform realistic simulations. The objective is…

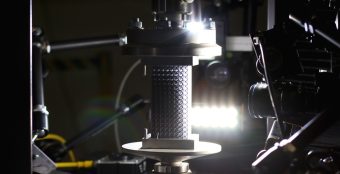

Design and validation of laser impact tests

ALPhANOV, an optics and lasers technology center based in Talence since 2007, and MBDA, the European leader in the Defence sector, have had a joint laboratory since 2019 for laser-matter interaction comprised of a cabin equipped with a high-power infra-red source. Thanks to a flexible and durable architecture, complex experiments, quickly reconfigurable, highly instrumented, and…

Detection monitoring of cracks with Digital Image Correlation: a choice tool

Context Some structures have a long service life from commissioning to replacement. These structures, when they have a fundamental role, must be able to maintain their physical integrity throughout their service life. To do this, it is essential to ensure their reliability over time. In the case of such structures as metal water pipes, different…

Digital Image Correlation for lattice structures

Why use Digital Image Correlation when testing lattice structures? This is what this article is about. Interest in lattice structures is growing rapidly for the development of aeronautical and space components in particular. In addition to the significant mass gains they allow to consider, they offer the possibility of optimising their behaviour based on their…

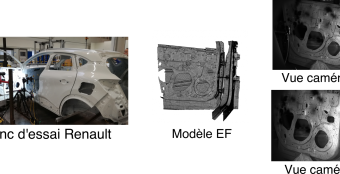

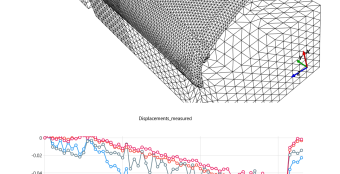

Digital Image Correlation for production monitoring – a collaboration with Renault and CETIM

Context As part of the large-scale production monitoring of automotive parts, it is essential to ensure that the reliability of the manufactured parts remains constant throughout the part’s production cycle. In order to make sure of this, parts are regularly sampled from production lines and tested to ensure that they still meet the required safety…

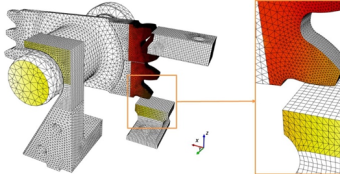

Validation of a mechanical test – a collaboration with MCE-5 DEVELOPMENT and MECATEST

EikoTwin DIC to validate your test kinematics, with MCE-5 DEVELOPMENT and MECATEST The purpose of a mechanical test is to submit a part or an assembly of parts to a specific stress in order to evaluate its elementary or in-service performances. The strong hypothesis, strengthened by theory or numerical simulation, is that the test bench…

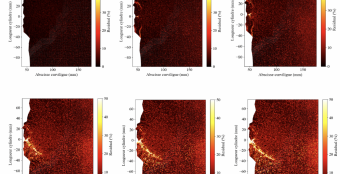

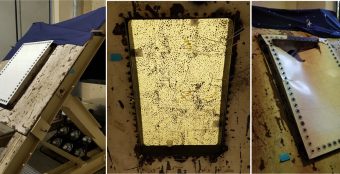

Toward quantitative image analysis of Bird strike tests

Redactors : N. Cordero, F. Fremy, M.Beneck for Saint-Gobain, F. Mathieu for EikoSim Aircraft radomes produced by Saint-Gobain are made of composite materials. In addition to the usual design requirements that these structures must comply with (lightness, aerodynamic shape, impact resistance), they need to be RF transparent so that the systems they shelter may function. This…