Posts by Team Eikosim

Altair Partner Interview

As an Altair partner, EikoSim was recently invited in Troy, MI for the 15th birthday of the Altair Partner Alliance. It was an occasion for our CEO Florent Mathieu to talk about our software offering and our views for the future. Want to know more about our validation solutions? Head on to our software portfolio. EikoTwin…

Read MoreThe Engineering Mind podcast – Testing and simulation

Recently, our CEO, Florent Mathieu, had the honor of joining Jousef Murad to discuss testing & simulation on his podcast, The Engineered Mind. In this conversation, Florent dives into the heart of what makes EikoSim a game-changer in the realm of structural simulation. From the intricate details of test preparation and instrumentation to the invaluable…

Read MoreCalibration of material parameters from a single test: workflow

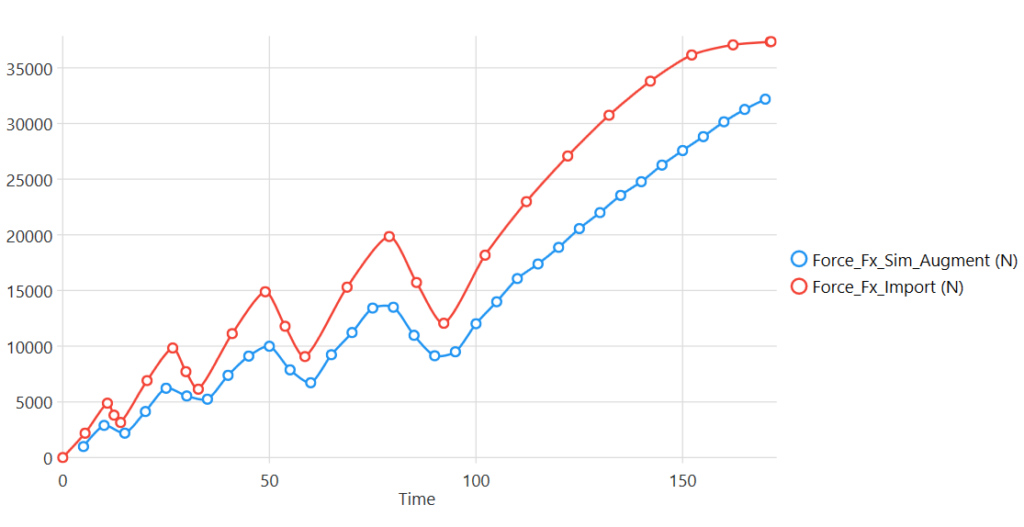

By Florent Mathieu, CEO of EikoSim. Images and data – credits IRT St Exupéry How can you perform calibration of several material parameters with a single test? Here’s a guide. In a previous article, we explored the possibilities offered by lattice structures and showed how it is possible to measure these complex kinematics using Digital…

Read MoreEikoSim announces partnership with simulation leader Ansys

EikoSim has recently announced a strategic integration partnership with Ansys, the global leader in engineering simulation. The collaboration aims at developing the field of simulation validation by incorporating EikoSim’s advanced image analysis and simulation validation tools with Ansys® Mechanical™ and Ansys® LS-DYNA®simulation softwares, benefiting Ansys’ extensive customer base. This partnership was forged through EikoSim’s efforts…

Read MoreVVUQ references & resources for solid mechanics & aerospace

By Florent Mathieu, CEO of EikoSim After several occasions where I’ve been given advice to consult specific documents in the field of validation testing and VVUQ (Verification, Validation, and Uncertainty Quantification), I’ve decided to write a blog about this. Here is a more detailed list of important papers, books or websites that I found along…

Read MoreWhat is VVUQ (Verification, Validation, and Uncertainty Quantification)?

By Florent Mathieu, CEO of EikoSim In the world of scientific simulations, ensuring accuracy, reliability, and credibility is of utmost importance. To achieve this, scientists and engineers employ a rigorous process called Verification, Validation, and Uncertainty Quantification (VVUQ). This blog article explores what VVUQ entails, its applications across various software product domains, and its role…

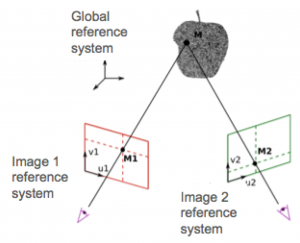

Read MoreDigital Image Correlation – The basics

By Florent Mathieu, CEO of EikoSim What is digital image correlation? The Digital Image Correlation (DIC) technique is a non-contact, full-field measurement approach that enables the assessment of the deformation and motion of objects. This is achieved by comparing digital images of the object before and after deformation. DIC measurement is a technique used to…

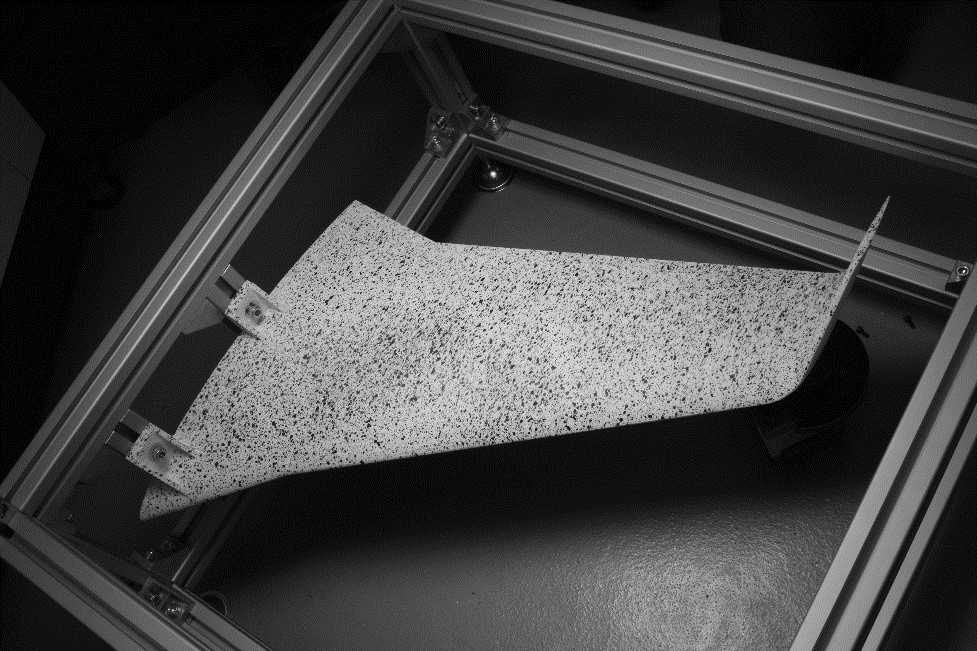

Read MoreHow to make a speckle pattern suitable for Digital Image Correlation?

Context: Speckle patterns & digital image correlation The principle of image correlation is based on tracking information from a so-called “reference” image in the following images, often called “deformed images.” When using digital image correlation (DIC), speckle patterns are created on the surface of a specimen to address uniqueness concerns. As a result, the accuracy…

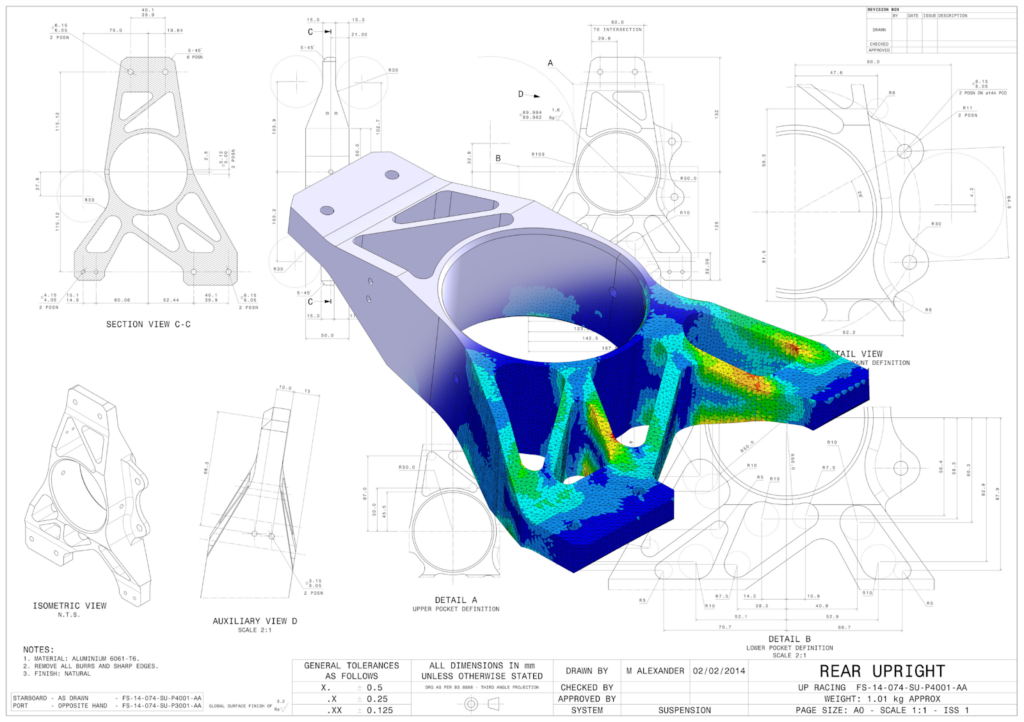

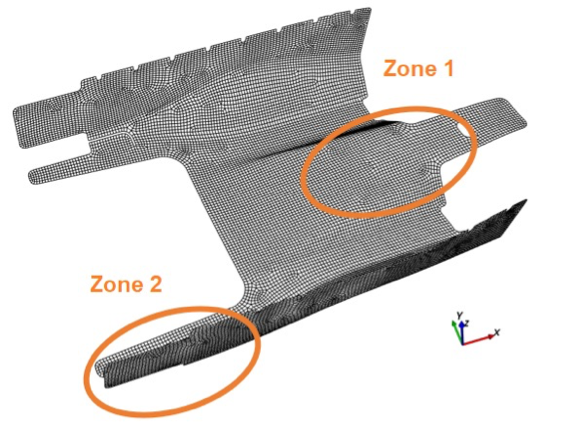

Read MoreIntegrating multi-camera DIC at MBDA

As part of its increasing competence in cutting-edge measurement techniques, MBDA has launched a process of testing and internal auditing of measurement resources by multi-camera DIC (Digital Image Correlation). After testing these measurement tools on coupon-type test campaigns, a new stage has been launched with the testing of this technology on more complex structures using multi-camera systems. Compressive…

Read MoreCrash-test and image correlation: how to measure seat deformations and follow the dummy’s movements

Crash tests are crucial in developing and certifying products, especially for the automotive, aeronautical, and railway industries. These tests simulate collision or impact scenarios in order to evaluate the resistance and safety of products. Among the equipment used to perform these tests is the reverse catapult, which is a device that projects an object, in…

Read More