EikoTwin Digital Twin

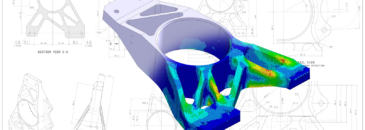

The EikoTwin Digital Twin is a highly effective tool to enhance simulation model calibration accuracy.

This innovative technology relies on digital models that are specifically calibrated using test data, ensuring that the resultant simulations provide highly accurate and reliable results.

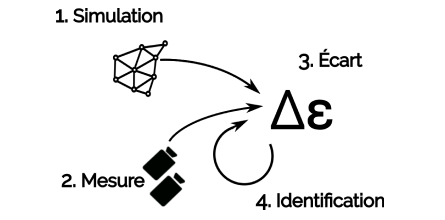

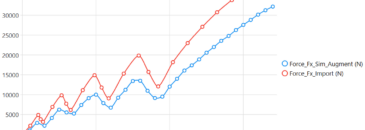

Digital twin technology implements "augmented simulations", which use the measured data as boundary conditions, but also allow simulation-enabled model calibration of material model parameters to bring the simulation closer to the expected result.

EikoSim's engineering partners and customers

Testimonials

Applications and tutorials

Altair Partner Interview

As an Altair partner, EikoSim was recently invited in Troy, MI for the 15th birthday of the Altair Partner Alliance. It was an occasion for our CEO Florent Mathieu to talk about our software offering and our views for the future. Want to know more about our validation solutions? Head on to our software portfolio. EikoTwin…

Recently, our CEO, Florent Mathieu, had the honor of joining Jousef Murad to discuss testing & simulation on his podcast, The Engineered Mind. In this conversation, Florent dives into the heart of what makes EikoSim a game-changer in the realm of structural simulation. From the intricate details of test preparation and instrumentation to the invaluable…

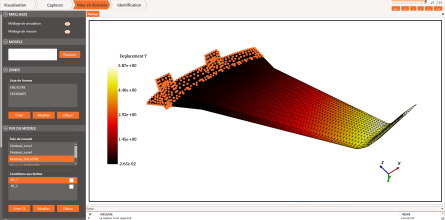

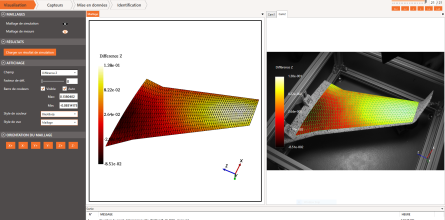

Calibration of material parameters from a single test: workflow

By Florent Mathieu, CEO of EikoSim. Images and data – credits IRT St Exupéry How can you perform calibration of several material parameters with a single test? Here’s a guide. In a previous article, we explored the possibilities offered by lattice structures and showed how it is possible to measure these complex kinematics using Digital…

EikoSim has recently announced a strategic integration partnership with Ansys, the global leader in engineering simulation. The collaboration aims at developing the field of simulation validation by incorporating EikoSim’s advanced image analysis and simulation validation tools with Ansys® Mechanical™ and Ansys® LS-DYNA®simulation softwares, benefiting Ansys’ extensive customer base. This partnership was forged through EikoSim’s efforts…

VVUQ references & resources for solid mechanics & aerospace

By Florent Mathieu, CEO of EikoSim After several occasions where I’ve been given advice to consult specific documents in the field of validation testing and VVUQ (Verification, Validation, and Uncertainty Quantification), I’ve decided to write a blog about this. Here is a more detailed list of important papers, books or websites that I found along…

What is VVUQ (Verification, Validation, and Uncertainty Quantification)?

By Florent Mathieu, CEO of EikoSim In the world of scientific simulations, ensuring accuracy, reliability, and credibility is of utmost importance. To achieve this, scientists and engineers employ a rigorous process called Verification, Validation, and Uncertainty Quantification (VVUQ). This blog article explores what VVUQ entails, its applications across various software product domains, and its role…

98-100 AVENUE ARISTIDE BRIAND

92120 MONTROUGE

FRANCE