EikoTwin DIC and the measurement of small strains

Innovation in the automotive industry Innovation is at the heart of the automotive industry: autonomous vehicles, shared mobility, advanced equipment, etc. In order to reinvent themselves and remain competitive, it is necessary for automotive industries to innovate and develop new technologies. It is therefore essential for these companies to perform realistic simulations. The objective is…

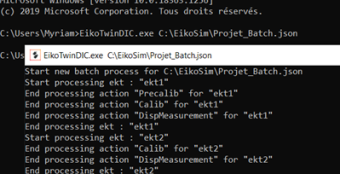

The Batch mode: a new EikoTwin DIC plugin

In order to continuously improve the features offered by EikoTwin DIC software, EikoSim has developed a new optional plugin: the Batch mode. It enables to launch the pre-calibration, calibration, and displacement measurement for several EikoTwin DIC projects in EKT format through a configuration file prepared beforehand. This partial automation of the data processing ensures significant…

IRT Saint-Exupéry trusts us with our software : EikoTwin

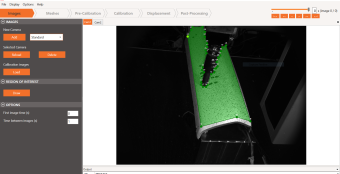

Ludovic Barrière is Project Manager at IRT Saint-Exupéry. He tells us about his experience with our software: EikoTwin DIC and EikoTwin Digital Twin. The software EikoTwin DIC in a few words EikoTwin DIC is an image-processing software dedicated to the link between measurements and numerical simulations. It uses a patented measurement technology to provide an…

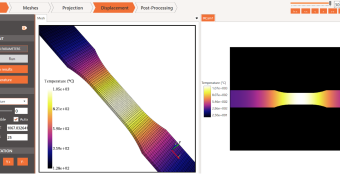

Safran Ceramics trusts EikoSim with the “Thermal” plug-in

Benjamin Lacombe is a Mechanical Design Engineer at Safran Ceramics. He tells us about his experience with EikoTwin DIC and the development of the “Thermal” plug-in. « I work at Safran Ceramics, Safran group’s center of excellence for high-temperature composites. We are in charge of developing high-temperature solutions for tomorrow’s aircraft. We conduct a large number…

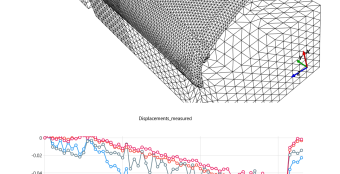

Technical functionality: selection of the measurement mesh

On EikoTwin DIC, the measurements are directly expressed on the simulation mesh. In order to choose which areas of interest for the test are visible to the camera(s), the so-called measurement mesh must first be selected. Indeed, this mesh will be the one where the results will be calculated. It is, therefore, essential to select…

Simulation validation with EikoTwin DIC

Simulation validation with EikoTwin DIC relies heavily on image processing. Image analysis methods provide full-field test data that can be used to validate and improve your simulation. Using the unique “Model-Based testing” method, EikoTwin DIC allows measuring displacements and strains of the observed parts directly on the simulation mesh. Thus, you will be able to…

Hybrid calibration: a robust alternative to self-calibration

Introduction This article is written as a complement to the article on good calibration practices recently published on our website. In general, it is very often possible to calibrate the camera system in EikoTwin DIC thanks to the knowledge of the geometry of the part, and of the correspondence between points of the model and…

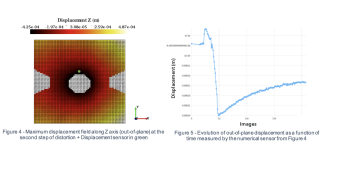

Design and validation of laser impact tests

ALPhANOV, an optics and lasers technology center based in Talence since 2007, and MBDA, the European leader in the Defence sector, have had a joint laboratory since 2019 for laser-matter interaction comprised of a cabin equipped with a high-power infra-red source. Thanks to a flexible and durable architecture, complex experiments, quickly reconfigurable, highly instrumented, and…

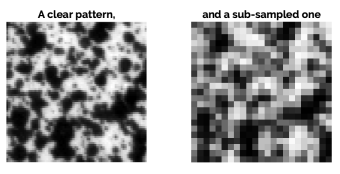

What is a good dic speckle pattern?

Concerned about making a new speckle pattern for your DIC experiment? In another article, we talked about the different techniques for creating a speckle pattern in digital image correlation, including the ability to vary the size and nature of the spots projected on the piece. But what size should your speckle pattern be? There is…

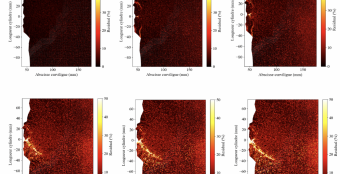

Detection monitoring of cracks with Digital Image Correlation: a choice tool

Context Some structures have a long service life from commissioning to replacement. These structures, when they have a fundamental role, must be able to maintain their physical integrity throughout their service life. To do this, it is essential to ensure their reliability over time. In the case of such structures as metal water pipes, different…

- « Previous

- 1

- 2

- 3

- Next »