EIKOTWIN RELEASE NOTES – SPRING 2023

The Spring 2023 release of the EikoTwin suite is available. Discover the details of the new features! On the menu of the EikoTwin Spring 2023 release, new features for all the software of the suite! Discover the main new features below. These improvements are also made available in EikoTwin DIC and EikoTwin Digital Twin. Feel…

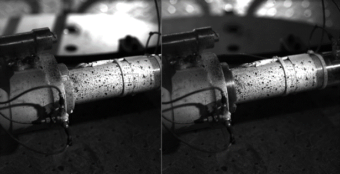

Digital Image Correlation (DIC) for vibration analysis

Digital Image Correlation (or DIC) is well-known for its static applications, but under the right circumstances, it is equally applicable to vibration testing. Here is an industrial example at Safran. As part of the development of increasingly high-performance aircraft actuators, Safran Landing Systems (SLS) must ensure the integrity of its systems during commissioning. With this…

EIKOTWIN RELEASE NOTES – AUTUMN 2022

The Autumn 2022 release of the EikoTwin suite is available. Discover the details of the new features! On the menu of the EikoTwin Autumn 2022 release, new features for all the software of the suite! Discover the main new features below. These improvements are also made available in EikoTwin DIC and EikoTwin Digital Twin. Feel…

How ArianeGroup improves simulation credibility with EikoTwin and DIC

Simulation credibility is a key aspect of the Virtual Testing concept. As the European leader in space launchers, Ariane Group participates with EikoSim in multiple Research and Development projects, including a RAPID R&D project (“MUTATION”) funded by the Direction Générale de l’Armement. This project aims at developing an industrial platform for test-simulation dialogue to meet…

FE simulation correlation: a dedicated platform

As an engineer, correlation of finite element simulation often requires lots of data management within Excel or with in-house Python scripts. As the European leader in space launchers, Ariane Group participates with EikoSim in multiple Research and Development projects, including a RAPID R&D project (“MUTATION”) funded by the Direction Générale de l’Armement. This project aims at developing an industrial…

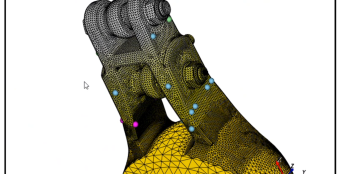

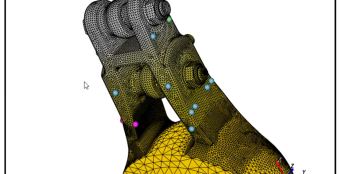

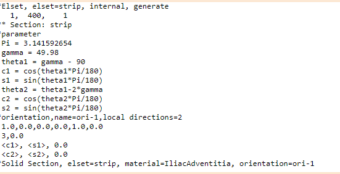

Simulation correlation with Abaqus: how far we’ve come in linking a solver to our software environment

Need to perform a correlation between an Abaqus simulation model and measurements automatically? Whether it is by developing a Python script, actually using the C++ API or developing our parsers, we have experimented a lot with reading and writing formats related to this solver, whether it is to correlate displacement or deformation fields or simply…

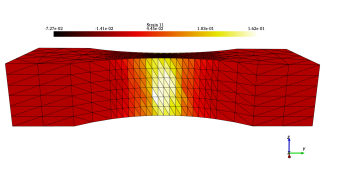

Mechanical regularization in EikoTwin DIC

In EikoTwin DIC, the measurement of displacement fields is performed on the simulation mesh. However, as this mathematical problem is by nature ill-posed, a mechanical regularization parameter allows the user to add mechanical conditions to the field measurements. Contrary to most digital image correlation software, at EikoSim, we have chosen to use a mechanical “filter”.…

Digital image correlation for crack measurement

In the context of crack propagation tests on composite material, EikoTwin image correlation solutions were used to meet a customer’s need. A post-processing script, exploiting the measurement data from EikoTwin DIC, was developed by EikoSim to bring satisfaction to the customer with a tailor-made solution. This work is part of Paul Nicolino’s engineering internship at…

EIKOTWIN RELEASE NOTES – SPRING 2022

By Florent Mathieu, Ceo of EikoSim The Spring 2022 release of the EikoTwin suite is available. Discover the details of the new features! On the menu of the EikoTwin Spring 2022 release, new features for all the software of the suite, and a newcomer! Discover the rest below, with first the presentation of EikoTwin Lite!…

Simulation validation in Excel, it’s over!

By Florent Mathieu, Ceo of EikoSim Ever wondered why you have to perform simulation validation of strain gauges in Excel ? In order to build more confidence in more refined simulation models, simulation models have to be backed up by a lot more real-world data, in order to avoid large design margins: teams now have…