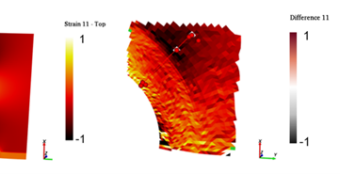

Forming and DIC: measurement of large deformations

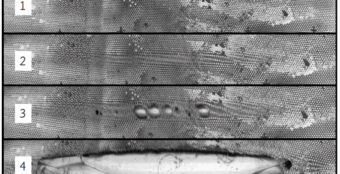

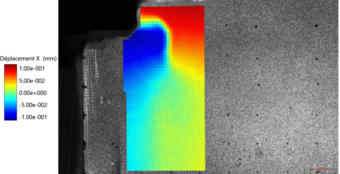

Experimental validation of forming processes, such as crimping, requires accurate characterization of local deformation fields, which can be achieved using DIC. A recent measurement campaign was conducted on an industrial part with severe geometric constraints, with an analysis area located on a section approximately 2 mm thick. Beyond the small size of the area of…

High-Speed DIC for Dynamic Analysis of Dashboard Opening during Airbag Deployment

This article showcases a use of high-speed DIC for validating the behavior of a dashboard opening. Passenger safety is a top priority in the automotive industry. In the event of a collision, the airbag must deploy quickly and effectively to protect the vehicle’s occupants. However, this ultra-fast process is directly influenced by the structure and…

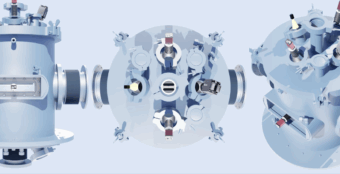

Design of a thermomechanical test bench using virtual simulation: integration of a thermal chamber for coupled DIC/IR imaging

This article was written in collaboration with Thibaut Archer, researcher at ONERA. Setting up thermomechanical tests in a controlled environment is a major challenge for validating numerical models in structural mechanics. Optimum design of the test rig is essential to ensure accurate acquisition of displacement and temperature fields, via DIC and IR measurements, particularly when…

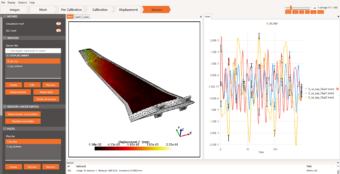

Measurement robustness and the use of “automatic meshing”: focus on synchronized calibration for DIC

Continuing our series of articles on best practices in Digital Image Correlation (DIC), today we present calibration using synchronized target images (with or without mesh alignment), a new procedure that enables the simultaneous determination of intrinsic and extrinsic camera parameters. This procedure complements the hybrid approach already available in EikoTwin DIC, which remains relevant when…

Your First DIC Experiment with EikoTwin: Setup Tips for Altair Users

As a user of the Altair Partner Alliance, you have free access to EikoTwin DIC — a powerful tool for full-field strain and displacement measurement through Digital Image Correlation (DIC). But while the software is directly accessible, many users hesitate to take the first step simply because they don’t have a dedicated experimental setup at…

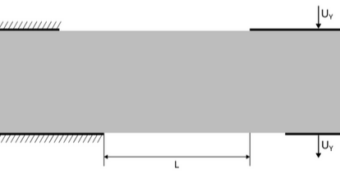

Designing optimized specimens for composite materials: from normative testing to simulation-assisted identification

This article is based on the M2 internship work of Antoine Vintache in collaboration with François Hild of the Laboratoire de Mécanique de Paris-Saclay, and presented at the ECCM21 conference [1]. This work is supported by ArianeGroup. In experimental mechanics, tests on composite materials are often based on standardized specimen geometries. These geometries – uniaxial…

Crack tracking on a structure : practical use case in thermal fatigue @ Liebherr Aerospace

In the aerospace industry, where component reliability is critical, the study and tracking of cracks is of paramount importance. Liebherr Aerospace, a leading manufacturer of heat exchangers, sought EikoSim’s expertise for an in-depth study of crack development under extreme thermal fatigue loading. The study, detailed below, provides a comprehensive overview of the methods, results and…

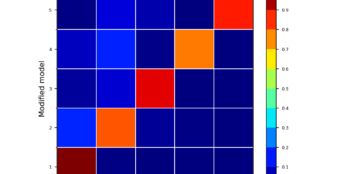

Modal analysis validation – in practice

In a recent post, we mentioned how DIC can be used for modal analysis validation by comparing the measured field with a finite element simulation. A practical exercise was proposed to us by INTES: how to export results to a simulation pre-post, in this case that of the PERMAS software? In this case, we have…

Building simulation credibility: the validation of Ariane 6’s Dual Launch Structure

Ensuring the credibility of simulation models is a concern in all fields of engineering. In aerospace engineering, structural qualification is a crucial step in ensuring that critical components are capable of withstanding the most severe operational conditions. This process is essential to ensure the safety and reliability of systems during missions. This article focuses on…

Modal analysis: how can Digital Image Correlation (DIC) help?

Modal analysis is a key technique used in engineering to understand the vibratory behavior of mechanical structures. It enables us to determine the natural frequencies and modal shapes of a structure, which are crucial in ensuring that it does not resonate dangerously under specific operating conditions. Traditionally, this analysis has relied on the use of…