What are good Digital Image Correlation test practices?

- By Floriane Soulas, R&D engineer at EikoSim

Importance of a good implementation of digital image correlation tests

When performing a test by using Digital Image Correlation (DIC), many parameters must be taken into account: brightness, speckle pattern, camera placement. All these steps are essential to achieve the best possible images, in order to get the maximum information from them. Indeed, neglecting one of these steps can lead to unusable images once the test is over. It will then be too late to take another set of images. Light management, speckle pattern creation and camera positioning are interdependent and must therefore be adjusted in parallel.

We will see together in this article, what are the good practices to implement when setting up a digital image correlation trial. This will ensure that the best possible images will be taken and usable afterwards.

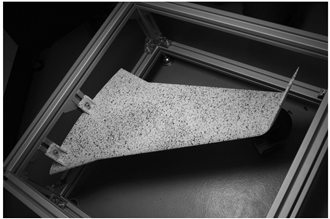

Speckle pattern

A digital image correlation test would be impractical without speckle pattern applied to the tested structure. Indeed, the principle of image correlation is based on the tracking of the texture of a so-called “reference” image in the following images, called “distorted images”. To make a speckle-free test adapted to the test envisaged is essential to provide a quality measurement. But this step can be delicate! You can find all our advice on how to make the best possible speckle pattern in our two articles dedicated to the subject (“How to make a speckle pattern suitable for digital image correlation?“, “What is a good digital image correlation speckle pattern?“).

Whether you create your speckle pattern in advance or on the day of the test, it is essential to respect certain precautions. It is important to take into account the drying time of the paint. The larger your study area, the longer you will have to wait for the paint to dry properly. This concerns in particular the undercoat (white or black) on which you will scatter the dots (black or white). Therefore, plan a specific time for this step, based on the recommendations of your paint supplier.

Camera positioning & adjustments

Once your study piece is speckled and installed on the test machine, you need to position your cameras. The camera(s) should be positioned so that they can see the entire speckled area. If you place more than two cameras, it is essential that the same area is seen by at least two cameras. Otherwise, the overlap condition will not be met, and analysis will not be possible.

It is advisable to think about the positioning of the cameras before the test in order not to be surprised on the D-day. For this, you can use our software EikoTwin Virtual. Indeed, it is not always easy to position the cameras when dealing with a crowded environment. Testing machines are not always located in open areas, which has to be taken into account. The presence of tools or related instrumentation can also obstruct the field of view of the cameras.

Here are the steps to follow to set up your cameras:

- Start by positioning your cameras facing the area to be observed, equipped with their lenses.

- Connect the cameras and launch your acquisition software, it will allow you to have real-time camera views.

- At first, reposition your cameras if necessary so that they visualize the whole area of interest. Pay attention to the pre-calibration points if they are in the room environment.

- Once this has been done, place the camera aperture on the weakest position. We will adjust the brightness later.

- Zoom (or unzoom) the camera lens as much as possible in order to blur the image. Then, camera by camera, reach the focus. For this step, it is recommended to zoom in on a well textured region of the image. This allows you to achieve the best possible focus.

- Check that your positioning allows you to follow the entire area of interest. Do not forget to keep your pre-calibration points in the camera field.

- Set the camera aperture to 4.

Lighting

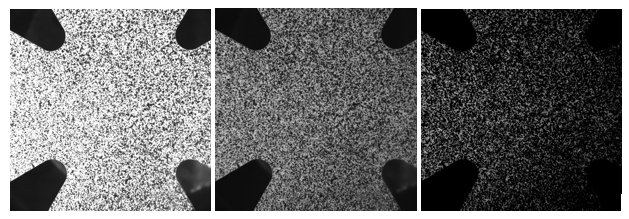

Lighting is one of the most important parts to manage during testing. Lighting must be homogeneous and constant throughout the test. It is therefore necessary to check the lighting conditions of the place beforehand and to try to control them as well as possible. Indeed, some test halls equipped with skylights or large windows without shutters may cause problems during the test. Outdoor weather conditions may change and thus alter the lighting of the images during the test. This can cause brightness jumps from one image to another and eventually distort the measurement. Similarly, the study area should be monitored for glare. These can interfere with the measurement and make the images unusable.

Here are a few steps to follow once your cameras are installed to check your lighting:

- Place your lamps facing the study area.

- Using the real-time images from the cameras, position them in order to obtain the most homogeneous lighting possible.

- If possible, turn off other lighting in the room that may interfere with yours during the test. For example: hallway lights that third parties might turn off by accident.

- Adjust the aperture of the cameras to obtain images that are neither too bright (saturated) nor too dark (under-lit).

Finally, it is important to mark out the test area during your tests. This to avoid that cameras and lights are moved (knocks, falling objects, etc…). Any modification of the set up during or after the beginning of the tests will make it impossible to use all the images. Indeed, the frame will be different from one image to another and the software will not be able to track between images.

Verification of the presence of the pre-calibration points in the field of view of the cameras

The issue of pre-calibration points, discussed earlier, is crucial if you are using EikoTwin DIC. Unlike most other digital image correlation software, EikoTwin DIC does not use a calibration target to perform camera calibration. The construction of the projection matrices is done by self-calibration. The idea is to use the nominal geometry of the part. This is defined in the finite element model. Using it, the camera system can be repositioned and reoriented directly in the 3D coordinate system of the part. Once the images have been created and loaded into the software, corresponding points must be clicked between the images and the digital model.

In order to analyze the images with EikoTwin DIC, it is necessary to check that a sufficient number of pre-calibration points are visible by all cameras. For this purpose, we recommend to perform preliminary virtual tests. These allow us to understand the test environment and to find the best possible placement for the cameras. The placement of the cameras is all the more important for the evaluation of the images because it conditions the presence of the pre-calibration points. Points that are essential for the analysis of the results by EikoTwin DIC.

If you have any questions about this, or about this video, you can contact us via the contact interface on our website. If you are interested in using the Blender software for your digital image correlation tests, we offer training courses in the use of the software applied to Digital Image Correlation in which we also present EikoTwin Virtual.