How ArianeGroup improves simulation credibility with EikoTwin and DIC

Simulation credibility is a key aspect of the Virtual Testing concept. As the European leader in space launchers, Ariane Group participates with EikoSim in multiple Research and Development projects, including a RAPID R&D project (“MUTATION”) funded by the Direction Générale de l’Armement. This project aims at developing an industrial platform for test-simulation dialogue to meet…

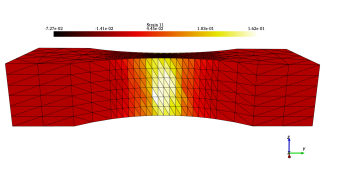

Mechanical regularization in EikoTwin DIC

In EikoTwin DIC, the measurement of displacement fields is performed on the simulation mesh. However, as this mathematical problem is by nature ill-posed, a mechanical regularization parameter allows the user to add mechanical conditions to the field measurements. Contrary to most digital image correlation software, at EikoSim, we have chosen to use a mechanical “filter”.…

Digital image correlation for crack measurement

In the context of crack propagation tests on composite materials, digital image correlation provides a wealth of useful information for characterizing crack advance and even the GIc. Case study from Safran. This work is part of Paul Nicolino’s engineering internship at EikoSim, who graduated from INSA Lyon in 2021 in Mechanical Engineering. The problem: highly…

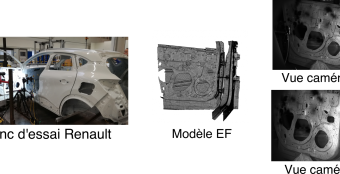

Digital image correlation for automotive structures

Context In the context of monitoring large-scale production of automotive parts, many parts are subjected to repeated tests to ensure their integrity once they are put into service. Thus, the test that we address in this paper is dedicated to the “gust of wind” tests of an opening structure (see Figure 1). Loading tests on…

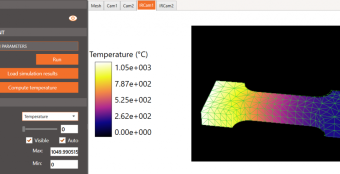

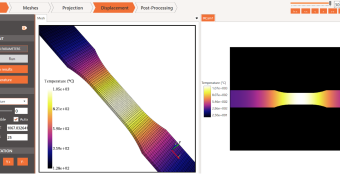

Thermal plugins from the EikoTwin suite

In order to meet the specific needs of customers and to extend the use of the EikoTwin software suite to other fields of activity, EikoSim has developed two new optional plugins: the DIC and DT thermal plugins. As their names suggest, DIC thermal plugin can be used in EikoTwin DIC software, and DT thermal plugin…

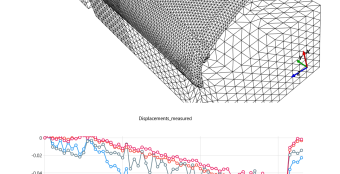

EikoTwin DIC and the measurement of small strains

Innovation in the automotive industry Innovation is at the heart of the automotive industry: autonomous vehicles, shared mobility, advanced equipment, etc. In order to reinvent themselves and remain competitive, it is necessary for automotive industries to innovate and develop new technologies. It is therefore essential for these companies to perform realistic simulations. The objective is…

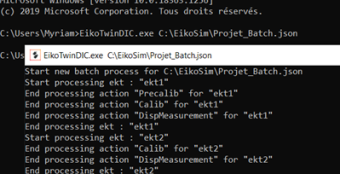

The Batch mode: a new EikoTwin DIC plugin

In order to continuously improve the features offered by EikoTwin DIC software, EikoSim has developed a new optional plugin: the Batch mode. It enables to launch the pre-calibration, calibration, and displacement measurement for several EikoTwin DIC projects in EKT format through a configuration file prepared beforehand. This partial automation of the data processing ensures significant…

IRT Saint-Exupéry trusts us with our software : EikoTwin

Ludovic Barrière is Project Manager at IRT Saint-Exupéry. He tells us about his experience with our software: EikoTwin DIC and EikoTwin Digital Twin. The software EikoTwin DIC in a few words EikoTwin DIC is an image-processing software dedicated to the link between measurements and numerical simulations. It uses a patented measurement technology to provide an…

Safran Ceramics trusts EikoSim with the “Thermal” plug-in

Benjamin Lacombe is a Mechanical Design Engineer at Safran Ceramics. He tells us about his experience with EikoTwin DIC and the development of the “Thermal” plug-in. « I work at Safran Ceramics, Safran group’s center of excellence for high-temperature composites. We are in charge of developing high-temperature solutions for tomorrow’s aircraft. We conduct a large number…

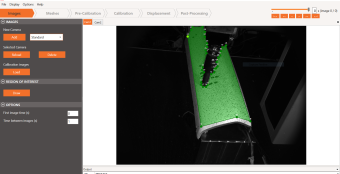

Technical functionality: selection of the measurement mesh

On EikoTwin DIC, the measurements are directly expressed on the simulation mesh. In order to choose which areas of interest for the test are visible to the camera(s), the so-called measurement mesh must first be selected. Indeed, this mesh will be the one where the results will be calculated. It is, therefore, essential to select…

- « Previous

- 1

- 2

- 3

- Next »