Posts by Team Eikosim

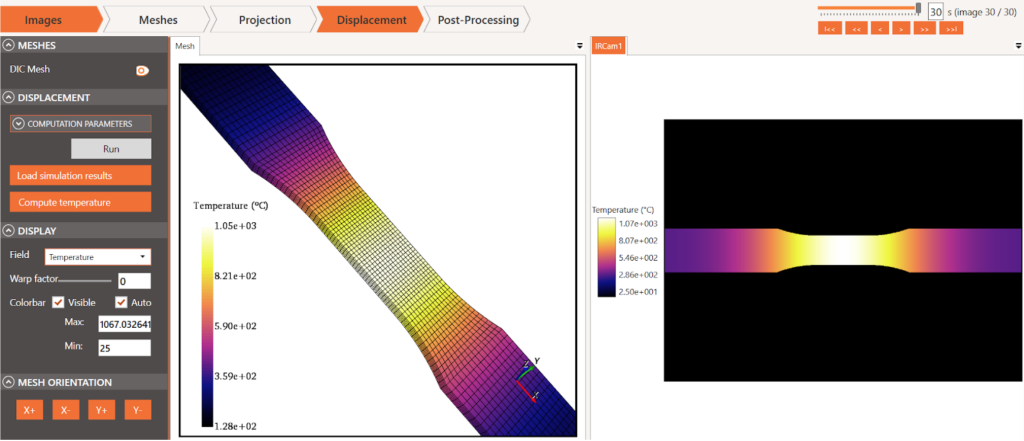

Safran Ceramics trusts EikoSim with the “Thermal” plug-in

Benjamin Lacombe is a Mechanical Design Engineer at Safran Ceramics. He tells us about his experience with EikoTwin DIC and the development of the “Thermal” plug-in. « I work at Safran Ceramics, Safran group’s center of excellence for high-temperature composites. We are in charge of developing high-temperature solutions for tomorrow’s aircraft. We conduct a large number…

Read MoreTechnical functionality: selection of the measurement mesh

On EikoTwin DIC, the measurements are directly expressed on the simulation mesh. In order to choose which areas of interest for the test are visible to the camera(s), the so-called measurement mesh must first be selected. Indeed, this mesh will be the one where the results will be calculated. It is, therefore, essential to select…

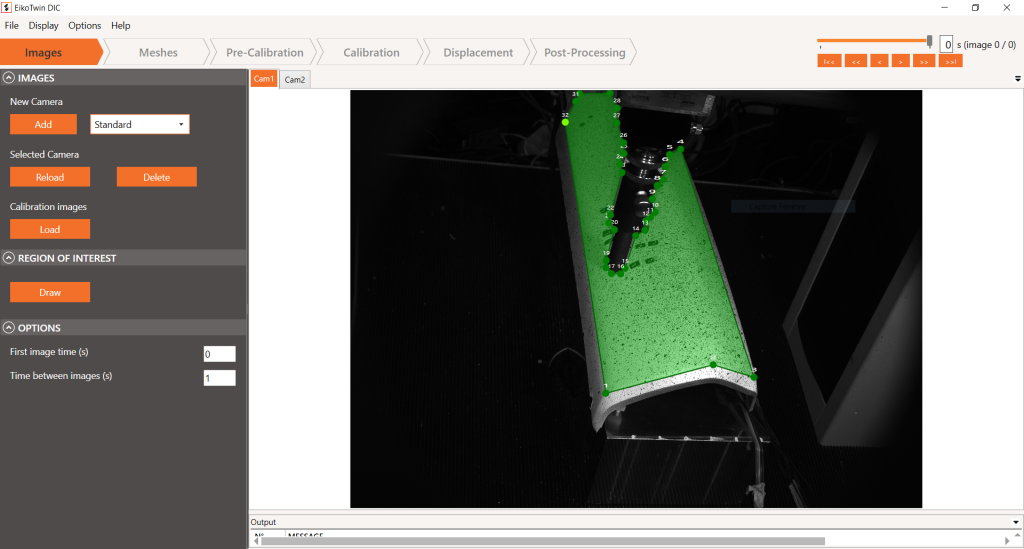

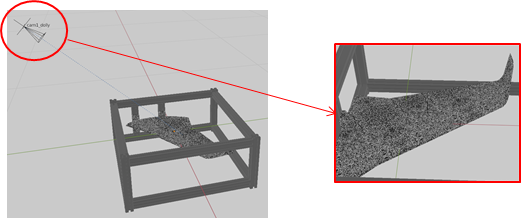

Read MorePreparation of your Digital Image Correlation test with Blender

This article invites you to care about an unexpected topic: the preparation of a digital image correlation test with Blender. While research articles do not always mention this aspect of digital image correlation measurements, test preparation is a crucial step in the procedure. The aim is to ensure that the images that will be taken…

Read MoreSimulation validation with EikoTwin DIC

Simulation validation with EikoTwin DIC relies heavily on image processing. Image analysis methods provide full-field test data that can be used to validate and improve your simulation. Using the unique “Model-Based testing” method, EikoTwin DIC allows measuring displacements and strains of the observed parts directly on the simulation mesh. Thus, you will be able to…

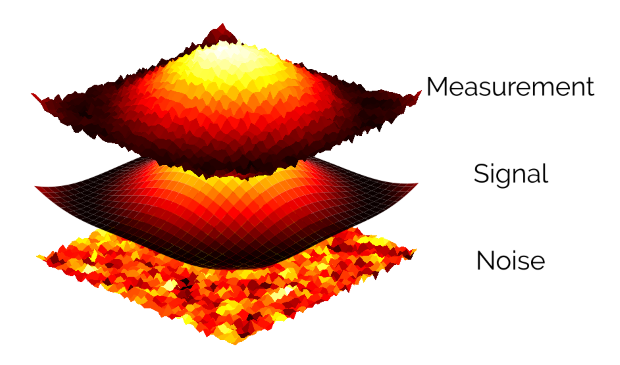

Read MoreMeasurement errors and digital image correlation

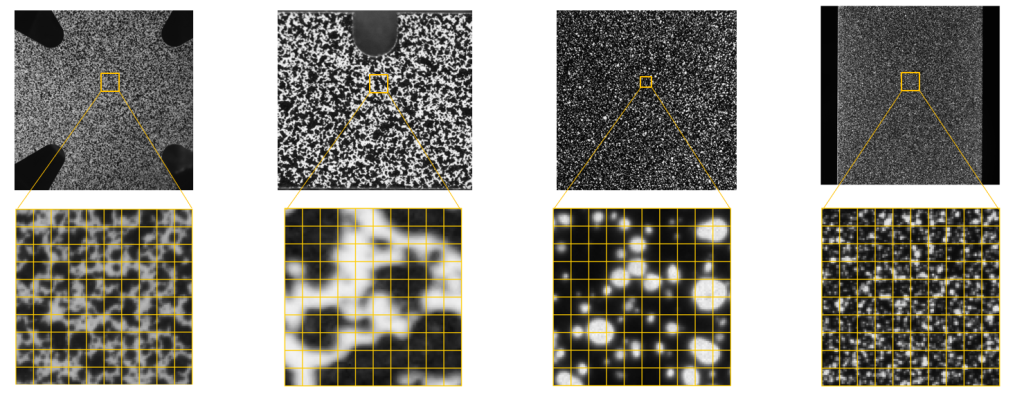

By Pierre Baudoin, R&D engineer at EikoSim When conducting a test campaign instrumented by digital image correlation, it must be possible to determine the characteristic measurement error for the quantities of interest studied (measured displacement or strain). This analysis is essential to know whether the measurement made is indeed the desired “signal” and not the…

Read MoreWhat are good Digital Image Correlation test practices?

Importance of a good implementation of digital image correlation tests When performing a test by using Digital Image Correlation (DIC), many parameters must be taken into account: brightness, speckle pattern, camera placement. All these steps are essential to achieve the best possible images, in order to get the maximum information from them. Indeed, neglecting one…

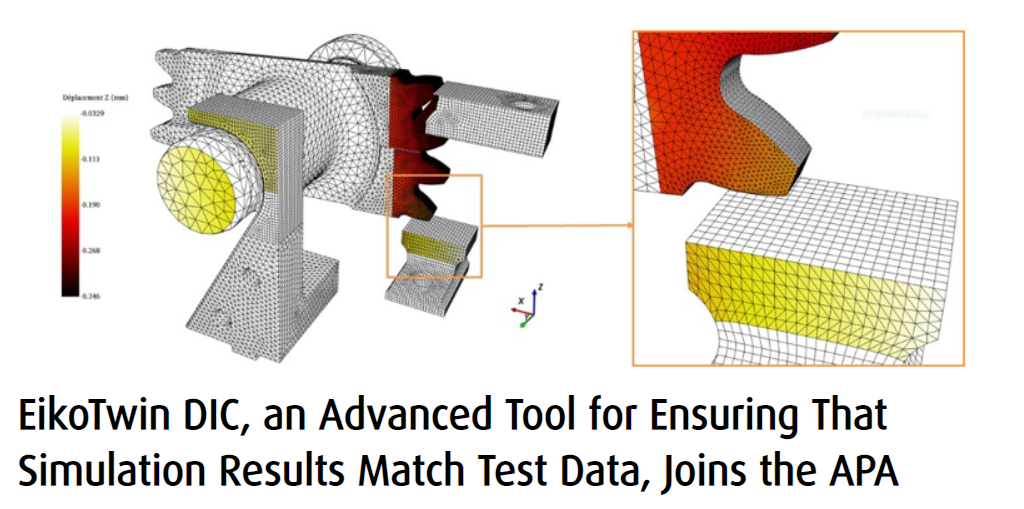

Read MoreEikoSim Joins the Altair Partner Alliance to Increase Its Footprint Among Simulation Customers

By Florent Mathieu, Ceo of EikoSim EikoSim today announced that it has become a member of the Altair Partner Alliance (APA), to provide its image analysis and simulation validation tools to Altair simulation software customers. This partnership came together after EikoSim’s efforts to develop compatibility between its EikoTwin software and Altair’s simulation suite, giving Altair customers…

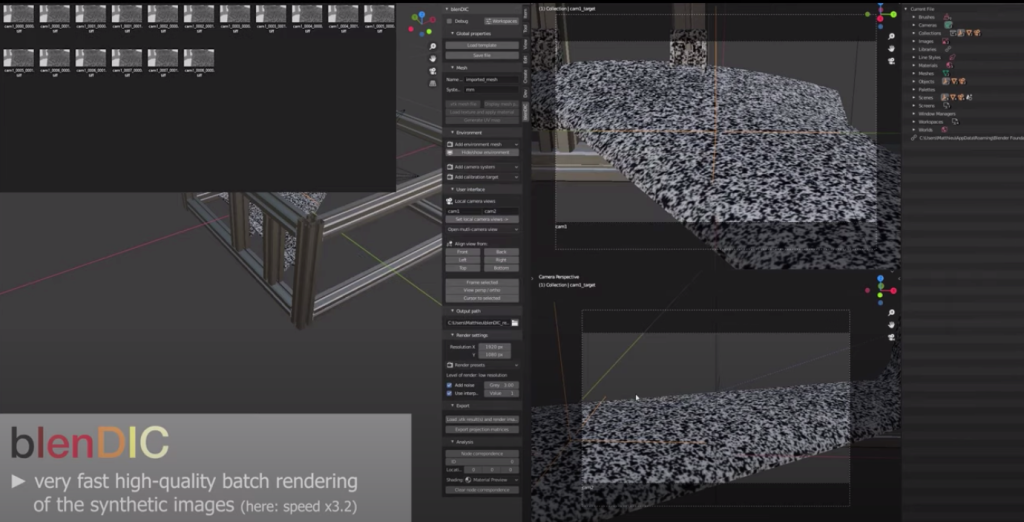

Read MoreEikoTwin Virtual: a support tool for the preparation of your virtual tests with Blender

The first stable version of the blenDIC add-on has been released. It is a photo-realistic image generation tool for setting up and performing virtual tests involving digital image correlation using the open source 3D animation software Blender. BlenDIC is an open source (GPL) add-on to Blender that encapsulates a large number of tools allowing Blender…

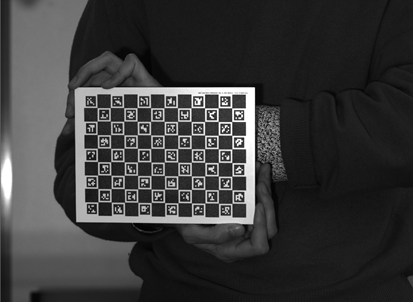

Read MoreHybrid calibration: a robust alternative to self-calibration

Introduction This article is written as a complement to the article on good calibration practices recently published on our website. In general, it is very often possible to calibrate the camera system in EikoTwin DIC thanks to the knowledge of the geometry of the part, and of the correspondence between points of the model and…

Read MoreSpeckle pattern size: how to calculate it for your DIC test?

In a previous article, we discussed how to choose the size of the speckle pattern for your experiment. We introduced the necessary parameters to control in order to optimize the size of your speckle for each of your tests. As mentioned, although the quality of a speckle pattern can only be analysed with respect to…

Read More