Validation of simulation models using DIC: Application to bird strike tests

In the aerospace and automotive industries, the resistance of structures to various high-speed threats is a guarantee of certifiability. In aerospace, certification for bird strike is a major issue for the safety and certification of equipment and systems. Tests are carried out not only to assess the structural integrity of materials, but also to validate the numerical models used in design. Simulation is playing an increasingly important role in product qualification and certification, reducing the need for costly and time-consuming physical testing. However, this transition to simulation requires rigorous validation of models based on reliable and representative experimental data.

Digital image correlation (DIC) is establishing itself as a key method for providing full-field data (displacements, strains) that can be directly used for calibration or validation of bird impact simulations. Unlike point sensors, DIC provides access to comprehensive spatial and temporal mapping of dynamic phenomena, which is essential for identifying sources of discrepancy between testing and simulation, thereby improving the predictive power of models.

In this context, EikoSim assisted Saint-Gobain Aerospace in analysing the behaviour of flat PMMA glazing subjected to bird strikes, using EikoTwin DIC software. The objective was twofold:

- Experimentally characterise the dynamic response of slabs (monolithic and laminated) under different impact scenarios.

- Provide reference data for the validation of finite element models, particularly in terms of displacement fields, strain, and crack propagation.

This study illustrates how DIC, combined with a rigorous calibration and post-processing methodology, can reduce test/simulation discrepancies and improve confidence in bird impact simulations. The results highlight the contribution of virtual sensors and correlation residual maps in detecting local phenomena (shock waves, crack initiation) that are difficult to capture using traditional methods.

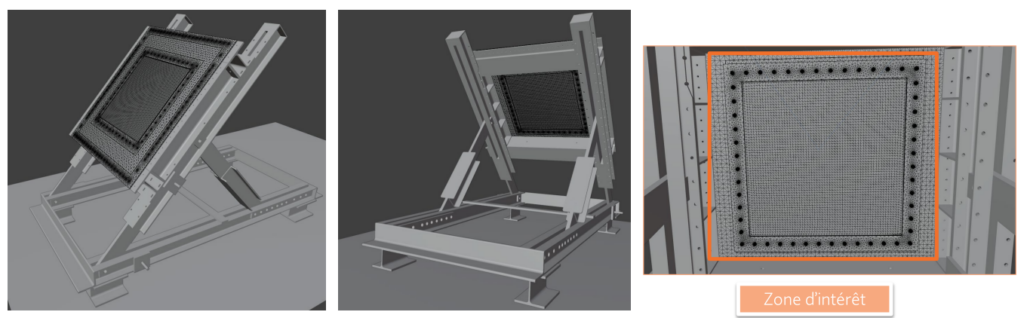

Description of the test bench and experimental protocol

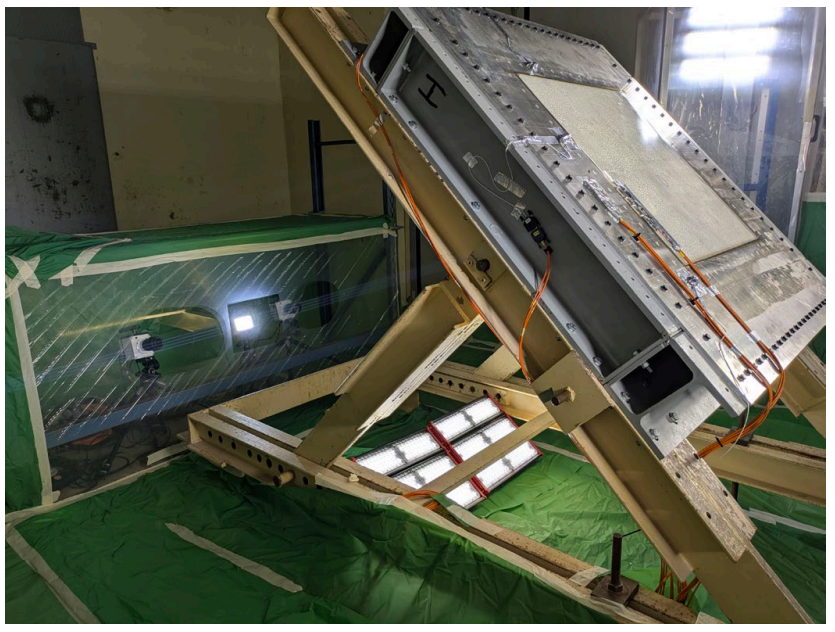

To reproduce the conditions of a bird strike impact, a specific test bench was designed, allowing a soft impactor to be projected at high speed onto PMMA plates (monolithic and laminated). The instrumentation was optimised to provide usable data for both experimental analysis and numerical model validation, with cameras positioned behind the impacted plates.

Experimental setup

The area of interest for the DIC measurement is a central area measuring 1000 x 1000 mm², including the plate and its retaining system (“metal retainer”). The acquisition system consists of:

- 2 high-speed cameras (Phantom VEO1310, 10 kHz) positioned in stereo (angle of 20°, inter-camera distance of 1,090 mm, measurement distance of 2,970 mm).

- Lenses: 50 mm (wide area) and 100 mm (localised area) focal lengths to adapt the spatial resolution to the needs of the analysis.

- Speckles: Random pattern applied using a stencil (characteristic size of 3 to 5 mm), optimised for the resolution of the cameras.

- Lighting: High-power LED panels to ensure sufficient contrast and minimise artefacts associated with rapid movements.

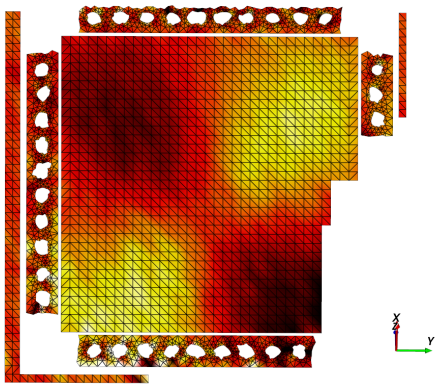

The objectives for model validation are based on several key aspects. Comparison of the displacement and strain fields obtained by DIC with those from simulations is made possible by direct projection of the experimental data onto the finite element mesh of the plate. This approach allows node-to-node analysis, which is essential for identifying discrepancies between test and simulation.

The detection of local phenomena, such as crack initiation and propagation, is ensured by appropriate instrumentation: a localised measurement area allows for detailed observation, while a wide area provides an overall view of the structural response.

Regarding test preparation, rigorous calibration was performed using a ChArUco test chart. This step made it possible to accurately determine the intrinsic and extrinsic parameters of the cameras, while correcting for optical distortions. Finally, synchronising the cameras and data acquisition with the impact trigger ensures exact temporal correspondence between the experimental images and the simulations, which is essential for robust validation of the numerical models.

Results and analysis

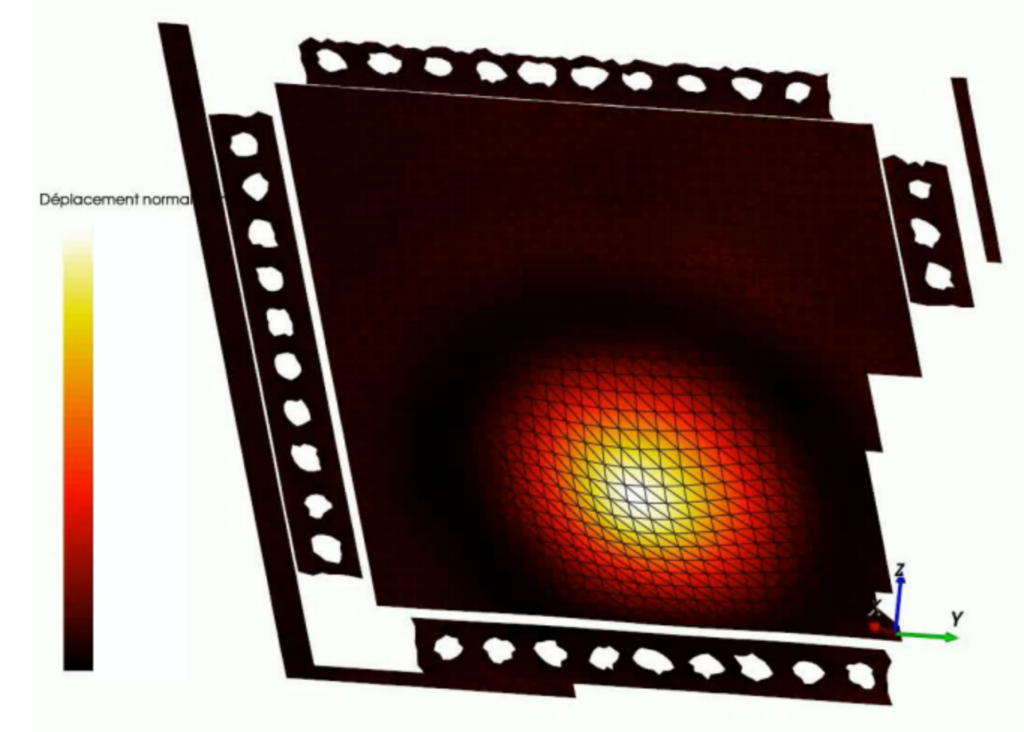

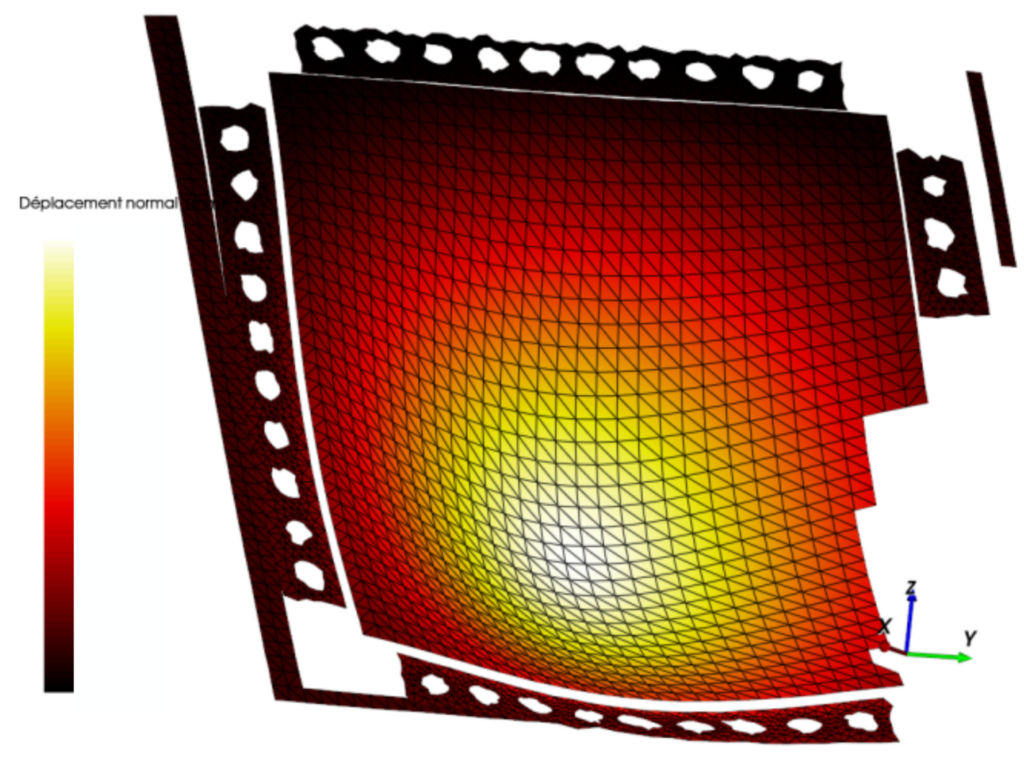

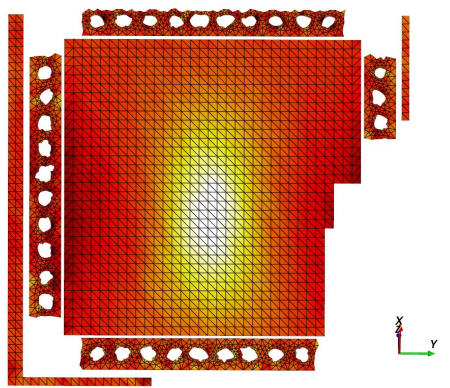

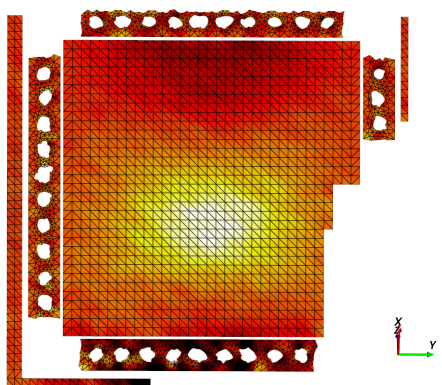

Bird impact tests instrumented by DIC provided complete displacement and strain fields on the PMMA plates, which can be directly used to validate finite element models. The main results and their interpretation are detailed below.

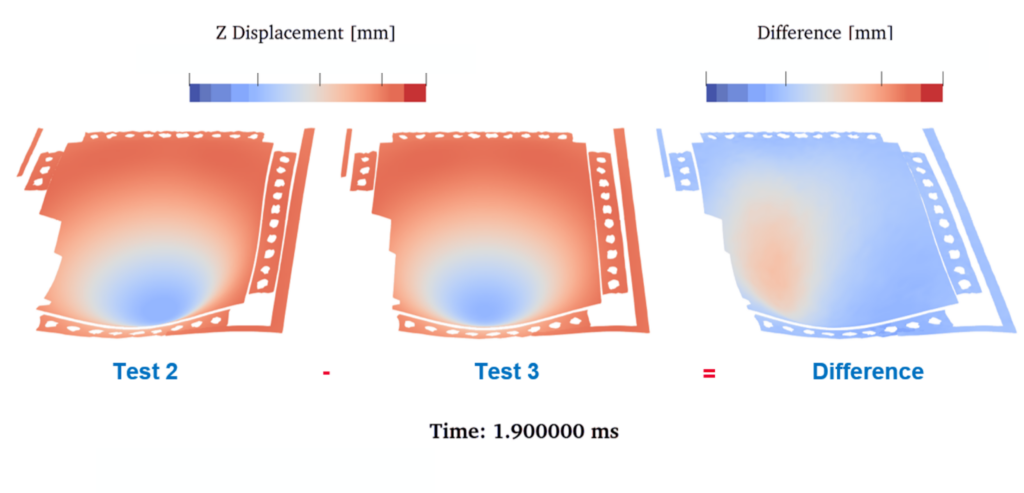

Analysis of the displacement fields provides a detailed temporal visualisation over a period of 10 ms. The normal displacement maps revealed very little dispersion between two successive tests at the same speed, with a peak amplitude observed between 2 and 4 ms after impact.

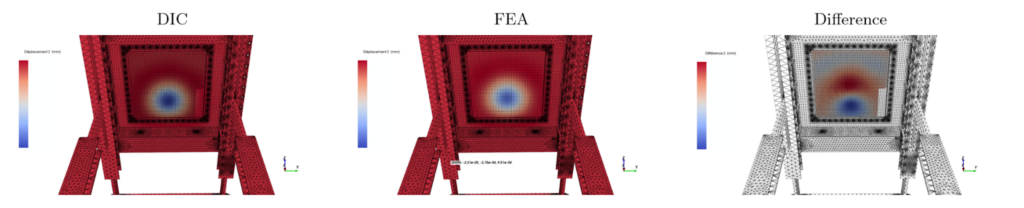

The comparison between the experimental fields and the simulation results shows good overall correlation, confirming the relevance of the models used. However, local deviations, particularly near the edges of the retainer, have been identified. These differences can be explained by a different point of impact between the test and the simulation and by certain modelling assumptions (non-linear behaviour laws required).

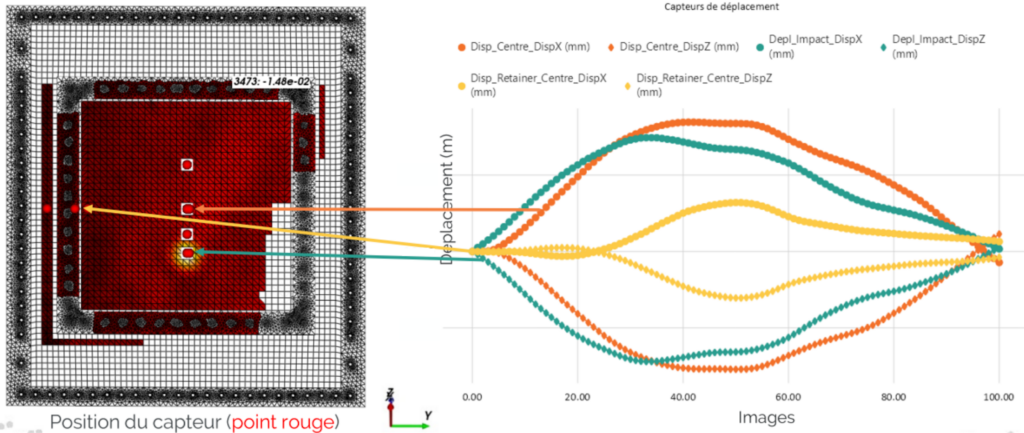

Analysis of data from virtual sensors makes it possible to track the evolution of displacement over time at strategic points, particularly at the centre of the plate and in the impact zone. The curves obtained reveal a typical dynamic response, marked by an initial displacement peak followed by gradually damped oscillations. These experimental results provide a valuable reference for adjusting the parameters of the numerical model, such as material parameters or damping coefficients, in order to improve the accuracy of the simulations.

Furthermore, the study of principal strains, such as E11 and E22, shows that they reach significant values in the impact zone. These observations confirm the need to use non-linear behaviour laws in simulations to accurately represent the response of the material under extreme stresses.

The analysis of the strain fields highlights detailed maps of the main strains E11 and E22. The results show that the maximum strains are concentrated around the point of impact, with a particularly marked asymmetry for laminated plates.

The study of correlation residuals reveals peaks organised in concentric circles, characteristic signatures of shock wave propagation. These areas of high residuals correspond to discontinuities. This approach allows for detailed validation of damage mechanisms and refinement of predictions of critical phenomena.

Analysis of the discrepancies between experimental results and simulations highlights several explanatory factors. In this type of model, modelling the contact between the soft impactor and the plate plays a key role: in this case, careful observation revealed that the position of the bird should be moved downwards on the plate. Furthermore, the non-linear behaviour of the PMMA itself contributes to these discrepancies. These elements highlight the importance of refining models to better represent real-life stress conditions.

The contribution of digital image correlation (DIC) to the validation of digital bird impact models is decisive in several respects. Firstly, DIC makes it possible to confirm the relevance of assumptions relating to boundary conditions, particularly with regard to the fixing of the plate by the retainer. Thanks to this method, it becomes possible to adjust the models if the discrepancy with the experimental result requires it, thus ensuring a more accurate representation of real conditions.

In addition, DIC excels at detecting non-linear phenomena, such as the appearance of cracks or delamination. This ability to capture complex phenomena enhances the robustness of simulations and enables more comprehensive model validation.

Discussion

This study demonstrates the major contribution of digital image correlation (DIC) to the validation of numerical models in dynamic tests such as “Bird Strike”. Digital image correlation (DIC) offers major advantages for validating digital models. Unlike point sensors, it provides complete displacement and strain fields, making it possible to precisely identify areas where simulations deviate from reality, such as around the retainer or during crack propagation. By extracting time curves at strategic points, virtual sensors offer unrivalled accuracy for calibrating model parameters such as elasticity modulus, damping or failure criteria.

However, this method is not without its challenges. The quality of the measurements depends heavily on the experimental conditions, particularly calibration, lighting and speckle. Inadequate preparation can introduce bias, particularly at high strain rates. Furthermore, bird strike-type impacts generate significant strain gradients that are difficult to capture even with fine meshes, highlighting the need to combine DIC with simulations for robust validation. Although measurement uncertainties in displacement remain low, on the order of 20 µm for displacements, they must be taken into account when interpreting discrepancies between tests and simulations, especially for local strains.

Compared to other measurement methods used in these bird impact tests, DIC stands out for its ability to provide a comprehensive view of phenomena, whereas strain gauges only deliver specific data points, which are often insufficient for validating complex 3D models. Unlike accelerometers, which are limited to measuring acceleration, DIC directly captures strains, thus providing much more relevant information for calibrating behaviour laws.

In the future, integrating DIC data into optimisation algorithms could enable automatic calibration of model parameters, such as PMMA behaviour laws or contact conditions. A hybrid approach, combining DIC with advanced numerical methods (such as SPH for the impactor and finite elements for the plate), would make it possible to better reproduce complex phenomena, such as shock wave propagation or progressive damage, which often occur during bird strikes.