High-Speed DIC for Dynamic Analysis of Dashboard Opening during Airbag Deployment

This article showcases a use of high-speed DIC for validating the behavior of a dashboard opening.

Passenger safety is a top priority in the automotive industry. In the event of a collision, the airbag must deploy quickly and effectively to protect the vehicle’s occupants. However, this ultra-fast process is directly influenced by the structure and materials of the dashboard. The dashboard skin deforms and eventually tears along predefined lines of weakness, releasing the airbag.

Despite advances in numerical simulation, accurately predicting the mechanical behaviour of skin remains a challenge. It is essential to ensure that failure occurs at the right place and at the right time, while validating numerical models and optimising the materials used. To address these challenges, the EikoTwin DIC solution, based on digital image correlation (DIC), was used at Forvia‘s facilities to capture and analyse the deformations and deformation rates of the dashboard skin at high speed. This study aims to improve understanding of the mechanisms involved, investigate the definition of a representative subsystem test, and refine simulation models to optimise dashboard design and ensure compliance with safety requirements.

Industrial context and challenges

🎯 Why is it crucial to study the dashboard opening?

- The impact on vehicle safety: to ensure controlled deployment in terms of opening the tearable skin, opening forces and the absence of projections, while reducing the need for airbag deployment tests.

- Although airbags are not directly subject to regulatory and normative constraints, they have nevertheless become standard equipment since the 1990s and enable compliance with safety standards and independent crash tests such as those conducted by EuroNCAP.

- Improvements in numerical simulation models are also necessary in order to obtain a comprehensive predictive model and reduce the need for costly physical testing.

- Establish new experimental methodologies to qualify materials based on high-speed DIC measurement results.

Understanding the phenomenon of dashboard opening

When the airbag is deployed, significant pressure is rapidly exerted on the dashboard, causing significant plastic deformation of the airbag flaps, particularly at their opening points, and propagating a rupture along the opening in the self-shearing complex of the skin. The resulting opening, which is intrinsically linked to the design and construction of the dashboard, remains a phenomenon whose precise kinematics and physics are difficult to predict. Consequently, a variety of tests exploring different configurations and conditions (particularly temperature) are essential for a comprehensive understanding of the process.

Objectives of the study

The tests carried out on the dashboard skin aim to precisely characterise its mechanical behaviour during airbag deployment, particularly in environments with extreme temperatures, ranging from very cold to very hot. The main measurements taken during these tests include calculating displacements to quantify the extent of deformation, identifying areas of maximum deformation where the skin is subjected to extreme stresses before rupture, studying deformation gradients around the opening lines, and finally, quantifying the speed of deformation in critical areas to assess the rapidity of the phenomenon.

The contribution of EikoTwin DIC: image correlation to aid understanding of material behaviour

EikoTwin DIC software was used to analyse the tests. It enabled precise measurement of displacement and deformation fields, an essential feature as it is performed in alignment with the finite element mesh. This precision makes it possible to identify critical stress and deformation zones with a high degree of accuracy, contributing to a better understanding of the dynamic behaviour of the dashboard during airbag deployment. In addition, the software facilitated the identification of critical areas by studying deformation gradients and enabled the monitoring of deformation rates, a determining factor in the analysis of failure conditions. Finally, the software offers the possibility of exporting results in various formats, including deformation curves and Altair H3D files.

Measurement method: high-speed digital image correlation (DIC)

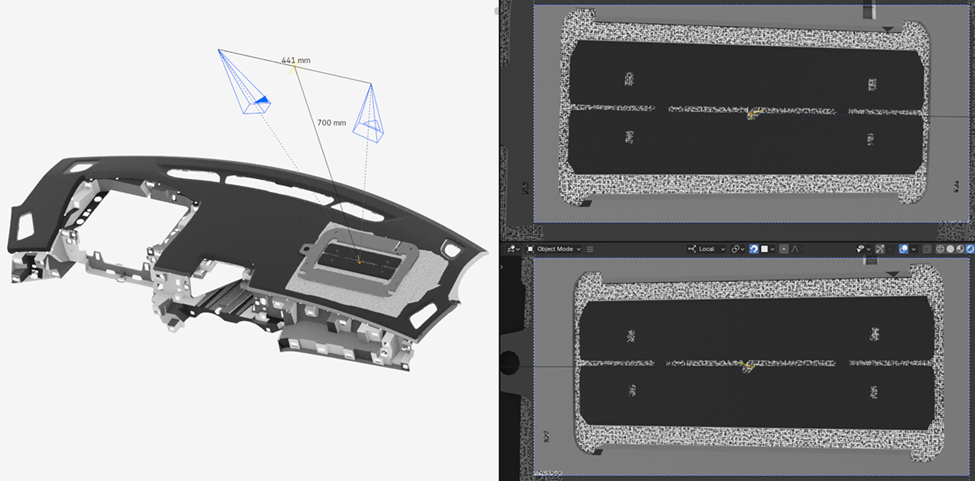

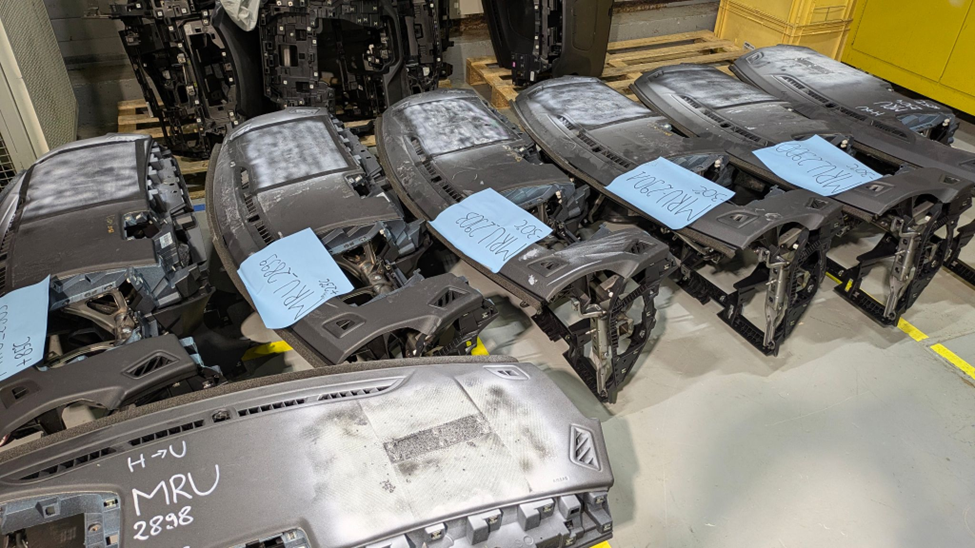

The high-speed digital image correlation (DIC) method was used to measure deformations. The testing instrumentation was rigorous, with tests carried out on dashboards under extreme temperature conditions ranging from -30°C to +85°C, and according to different airbag deployment configurations. To optimise set-up time, which is often long and complex due to the adjustments required for optimal data acquisition, a virtual test scene was implemented in the EikoTwin Virtual tool. This proactive approach improves each stage of preparation: it allows the ideal positioning of cameras to be determined using a virtual simulation that takes into account the required field of view and geometric constraints, thus avoiding time-consuming manual repositioning during physical set-up.

Virtualisation also facilitates the selection and installation of equipment by allowing the list of necessary hardware and accessories to be precisely defined in advance. Finally, it allows potential obstructions to be anticipated and managed and visibility to be optimised by simulating the dynamics of the test, including the rapid deployment of the airbag and the gradual obscuration of the field of vision, and by adjusting the positioning of the cameras accordingly. Thanks to this comprehensive virtual preparation, deployment on the test bench is streamlined and accelerated, with the initial configuration being directly operational as soon as physical installation is complete, thus limiting downtime around the test machine.

The acquisition conditions were rigorously defined to capture the ultra-fast dynamics of the airbag deployment. A very high acquisition frequency, in the order of several thousand images per second, was used to accurately track the opening. Phantom T4040 cameras (up to 9,350 frames per second at a maximum resolution of 4.2 Mpx) were chosen in order to maximise the information obtained. To ensure image sharpness and avoid motion blur, a fast shutter speed of a few tens of microseconds was selected. The depth of field was adjusted to keep the dashboard surface in focus throughout the test, with verification carried out beforehand and during the experimental setup. Finally, the visibility of the opening was optimised as much as possible by anticipating the gradual obstruction of the field of vision by the airbag using data from previous tests, and by adjusting the positioning of the cameras to maximise coverage of the area of interest throughout the test.

To prepare the parts for measurement, random speckles were applied to their surface. This speckle pattern was created using spray paint and a grid, producing spots approximately 1 mm in size. It should be noted that particularly careful application of the speckle pattern is essential to ensure the accuracy of the measurements obtained using the digital image correlation method.

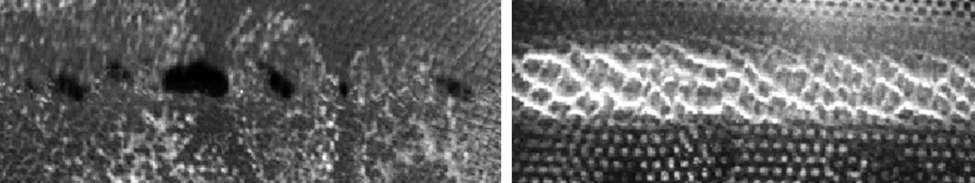

A specific treatment for the speckles was implemented for tests carried out at extreme temperatures, particularly low temperatures. A dedicated study was conducted to define a method for applying the speckles that would guarantee their resistance to these conditions and ensure the quality of the measurements throughout the tests. In particular, for parts tested at -30°C, a layer of black grease was applied before the paint was sprayed on. This protocol proved crucial in preventing the paint from flaking off under the effect of severe deformation at low temperatures, a phenomenon which, without this precaution, would have compromised the reliability of high-speed DIC measurements in the area of maximum deformation before fracture (figure). The use of this grease base made it possible to maintain the convergence of the DIC calculations until failure, even in highly stressed areas, with low correlation residues, demonstrating high-quality pattern tracking (figure). Conversely, the absence of grease resulted in higher correlation residues, indicating a loss of accuracy. Applying white paint directly to the surface prepared with grease, while limiting the amount sprayed, optimised the adhesion and durability of the speckles, even under the severe conditions of low-temperature testing and airbag deployment.

Airbag deployment phases

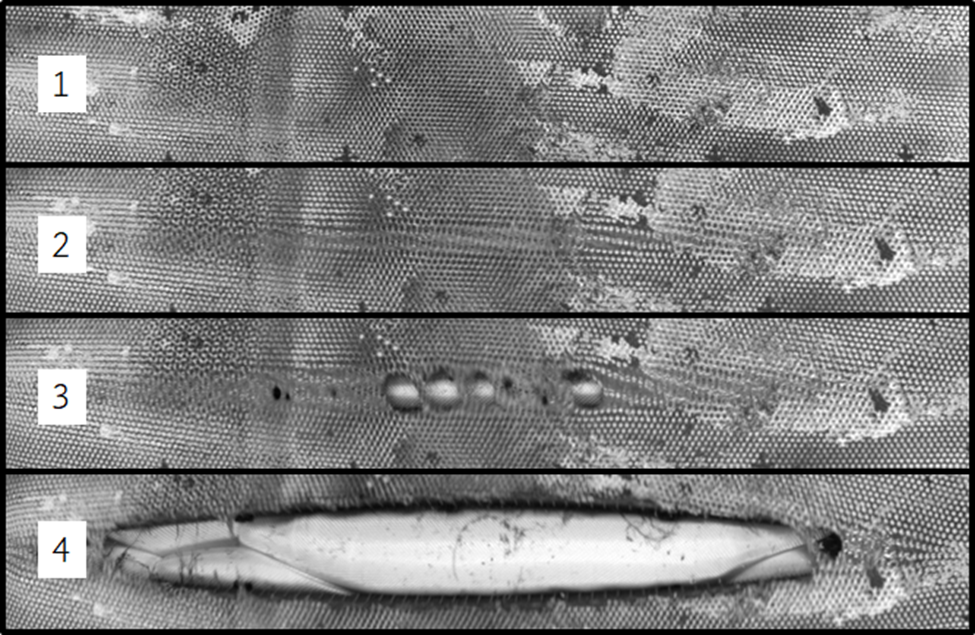

The opening of the dashboard during airbag deployment takes place in four key stages, illustrated in the corresponding figure. 1. Initial state: before deployment, the dashboard is intact and in a static position. 2. Deformation of the skin: activation of the airbag initiates a phase of progressive deformation of the material under the effect of pressure. 3. Skin rupture: the skin breaks along predefined lines of weakness, initiating the opening process. 4. Propagation of the rupture: the opening spreads rapidly under the effect of the airbag’s rising pressure, completing the deployment process.

High-speed DIC measurement results: Displacements and deformations

Deformation measurements revealed maximum deformations of up to 150% in certain critical areas, enabling accurate characterisation of the material up to the point of failure. Significant differences were observed depending on the type of dashboard skin. The influence of temperature was also found to be significant. At high temperatures (+85°C), maximum deformation increased, indicating more ductile behaviour of the material. Conversely, at low temperatures (-30°C), maximum deformation was lower and fracture more abrupt.

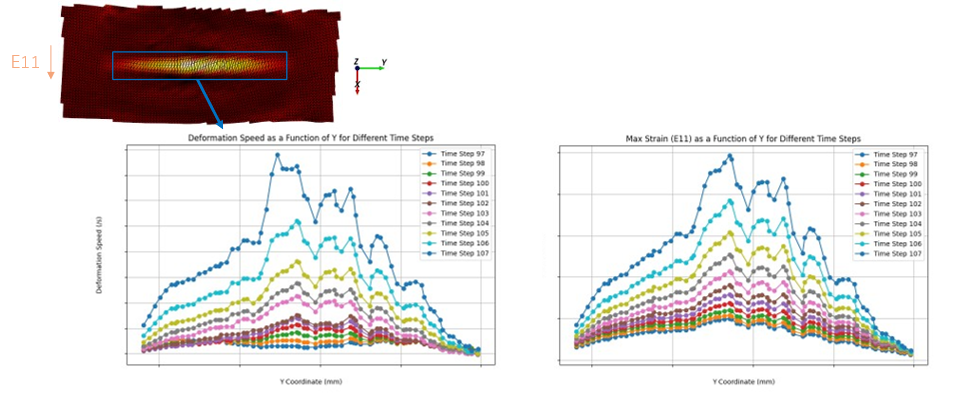

Deformation speed and maximum deformations

One of the main objectives of this study was to locate areas of stress concentration and quantify the maximum deformation rate within these critical areas. Using EikoTwin DIC software, it was possible to precisely locate these areas, measure the maximum deformation just before failure with an average uncertainty of 1.5 × 10⁻⁴, and track the maximum deformation rate. In addition, high-speed DIC made it possible to compare the influence of temperatures on the mechanical behaviour of the dashboard skin and to guarantee high measurement accuracy, with displacement uncertainty of less than 1.5 µm.

Conclusions

This study provided in-depth insight into the complex mechanisms governing the opening of a dashboard during airbag deployment. Thanks to high-speed image acquisition and analysis of the measurements obtained, it was possible to accurately locate critical stress concentration areas, quantify significant deformation levels and track deformation speed dynamics, while incorporating a rigorous assessment of measurement uncertainties. In addition, this research enabled rapid validation of the actual stress conditions on the materials in the early stages of the project. This validation proved decisive in guiding Forvia, a major player in the automotive industry, in defining targeted measurement campaigns for material properties. Finally, the importance of meticulous test preparation was confirmed, with sensor positioning optimisation and measurement repeatability playing a key role in the success of this study. The results obtained thus provide valuable insights into material stress conditions, contributing significantly to the development and optimisation of automotive structures.

Information : contact {AT} eikosim.com