EikoTwin Digital Twin — FEA Model Updating with DIC

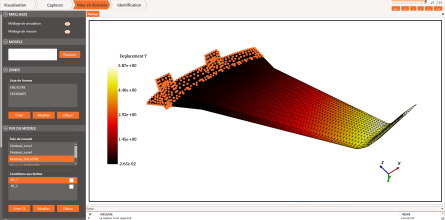

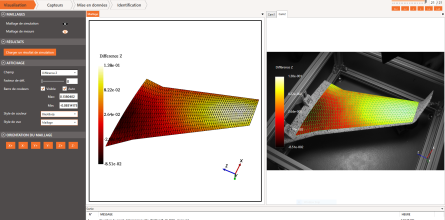

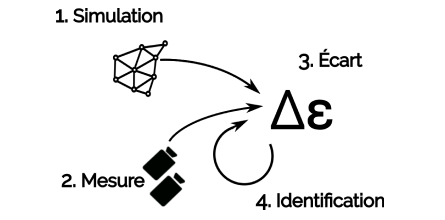

The EikoTwin Digital Twin is a highly effective tool to enhance simulation model calibration accuracy.

This innovative technology relies on digital models that are specifically calibrated using test data, ensuring that the resultant simulations provide highly accurate and reliable results.

Digital twin technology implements "augmented simulations", which use the measured data as boundary conditions, but also allow simulation-enabled model calibration of material model parameters to bring the simulation closer to the expected result.

EikoSim's engineering partners and customers

Testimonials

Applications and tutorials

Local DIC or Global DIC: Which is the Best Method for Your Application?

Introduction Digital Image Correlation (DIC) relies on two main algorithmic families: local DIC (or subset-based) and global DIC (or FE-based). Both approaches produce displacement and strain fields, but their internal workings, strengths, and limitations are fundamentally different. For a test engineer choosing a DIC system or software, understanding this distinction is essential – it directly…

EikoTwin v2026.1 – release notes

EikoTwin DIC The new version of EikoTwin DIC includes a brand new Python API, simplifies marker tracking, and enables new analyses. EikoTwin Vision We spent hours fine-tuning EikoTwin Vision’s behaviour to make it simpler, faster and more enjoyable to use. EikoTwin Digital Twin EikoTwin Digital Twin receives a host of improvements with more robust analysis…

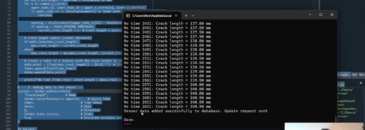

EikoTwin DIC Python API demo

We are pleased to present our new Python API, designed to facilitate integration and automation of analyses with EikoTwin DIC. This API allows users to take full advantage of digital image correlation (DIC) results with customised post-processing. Its goal is to simplify our users’ workflows by providing a flexible and powerful interface for interacting with…

FEA Model Validation with DIC — Bird Strike Impact Testing

In the aerospace and automotive industries, the resistance of structures to various high-speed threats is a guarantee of certifiability. In aerospace, certification for bird strike is a major issue for the safety and certification of equipment and systems. Tests are carried out not only to assess the structural integrity of materials, but also to validate…

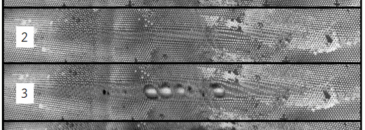

Forming and DIC: measurement of large deformations

Experimental validation of forming processes, such as crimping, requires accurate characterization of local deformation fields, which can be achieved using DIC. A recent measurement campaign was conducted on an industrial part with severe geometric constraints, with an analysis area located on a section approximately 2 mm thick. Beyond the small size of the area of…

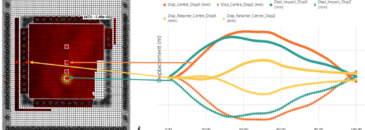

High-Speed DIC — Full-Field Measurement of Airbag Deployment

This article showcases a use of high-speed DIC for validating the behavior of a dashboard opening. Passenger safety is a top priority in the automotive industry. In the event of a collision, the airbag must deploy quickly and effectively to protect the vehicle’s occupants. However, this ultra-fast process is directly influenced by the structure and…

98-100 AVENUE ARISTIDE BRIAND

92120 MONTROUGE

FRANCE