EikoTwin DIC and the measurement of small strains

- By Lucas Angénieux, Research engineer at EikoSim

Innovation in the automotive industry

Innovation is at the heart of the automotive industry: autonomous vehicles, shared mobility, advanced equipment, etc. In order to reinvent themselves and remain competitive, it is necessary for automotive industries to innovate and develop new technologies. It is therefore essential for these companies to perform realistic simulations. The objective is to predict the behavior of their innovative parts in order to anticipate their production and future use. This is why these simulations must accurately represent both the geometry and mechanical behavior of the tested part. However, their validation also requires to reproduce the boundary conditions actually experienced by the test part. In this article, we will particularly focus on the behavior of a dashboard during low mechanical strains stress in compression.

Measurement of small strains thanks to digital image correlation

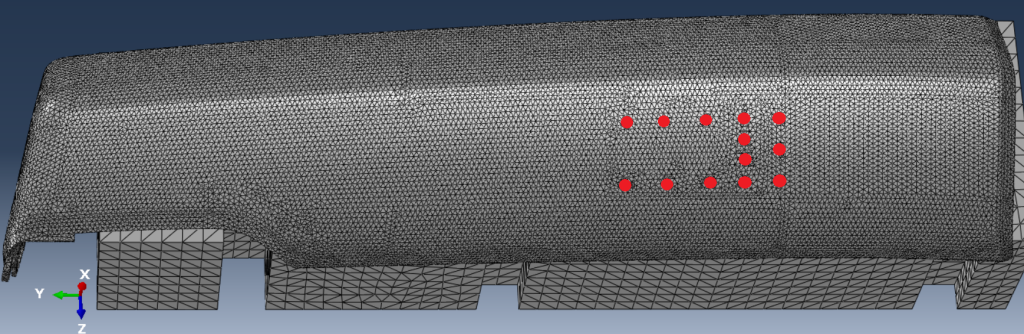

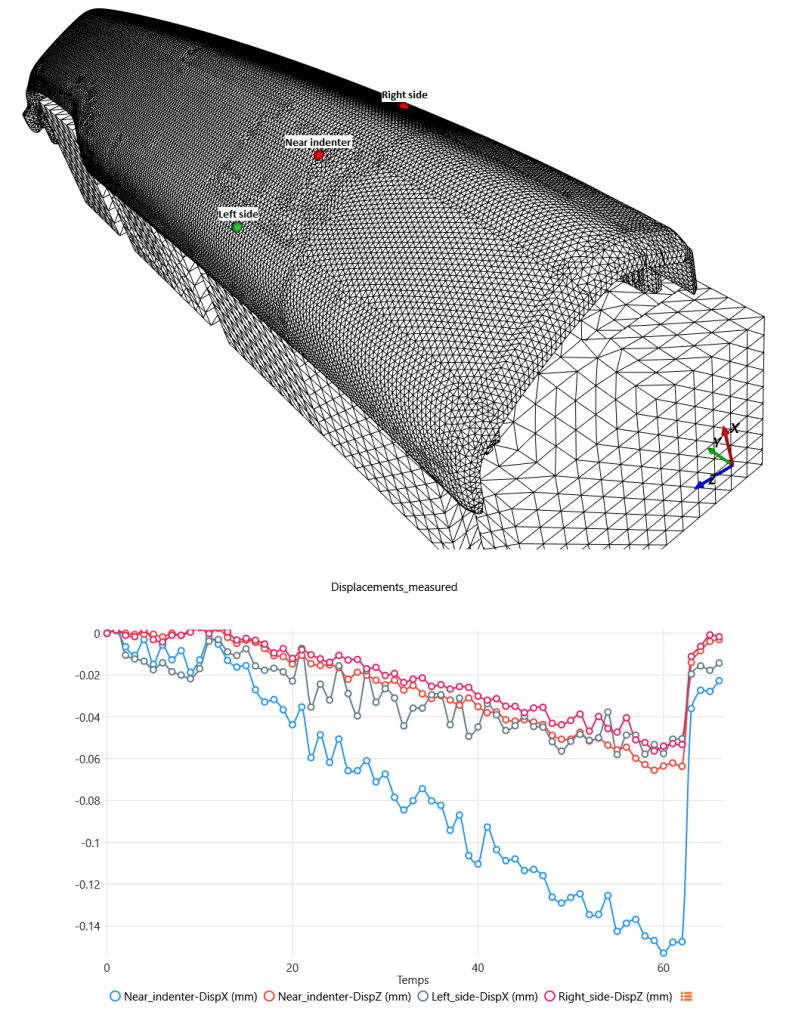

The digital image correlation based on the global method answers this problem. Indeed, it allows to measure a displacement field defined directly in the reference frame and on the nodes of the simulation mesh (Figure 1).

Experimental set-up

The purpose of the test under consideration is to determine the overall mechanical response of the dashboard when the user presses on one of the 13 points shown in red in Figure 1. In the test, we approximate the user’s action by the application of a 10N vertical compression force.

Such loads are representative of forceful contact by the user. For this level of force, the overall strains lived by the part remain small. Thus, this is one of the challenges of the test for the involved measurement technologies.

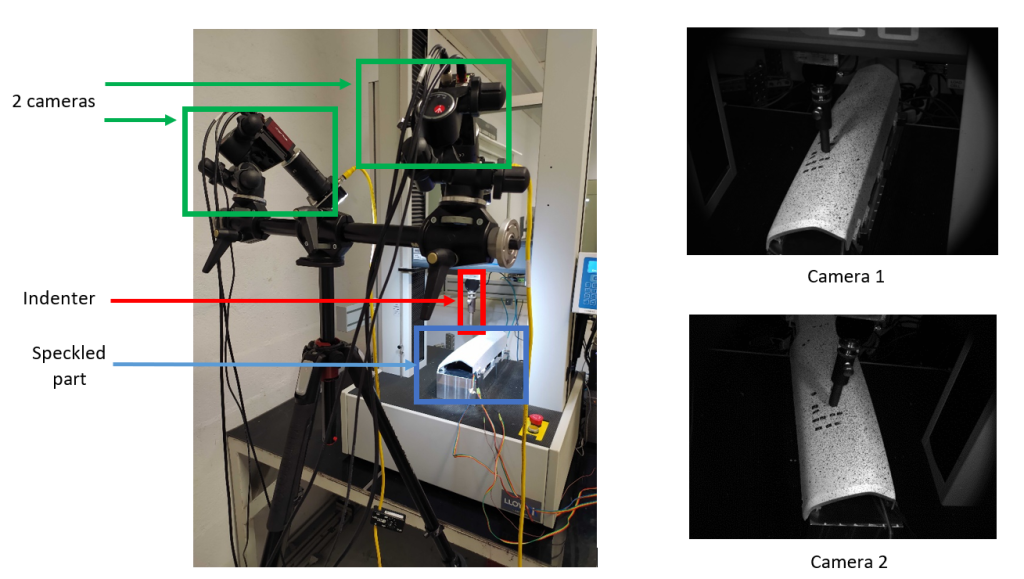

In order to carry out the measurements by image correlation, a speckle is made on the part using paint cans. The application of a texture to the part is necessary to follow the surface of the cameras. Therefore, we can process the measurement of the experimental displacement fields. Once the part is painted, it is placed under an indenter on a rigid aluminum frame.

The indenter then applies a linear force from 0 to 10N on each of the 13 points selected for the study. The follow-up of the surface displacement of the part is ensured by a pair of cameras that acquires the images of the test. We finally obtain 60 images per camera for each ramp-up (Figure 2).

Images post-processing on EikoTwin DIC

The 13 sets of images are then post-processed using the EikoTwin DIC software. This allows us to measure the evolution of the surface displacements of the part for each of the loading points.

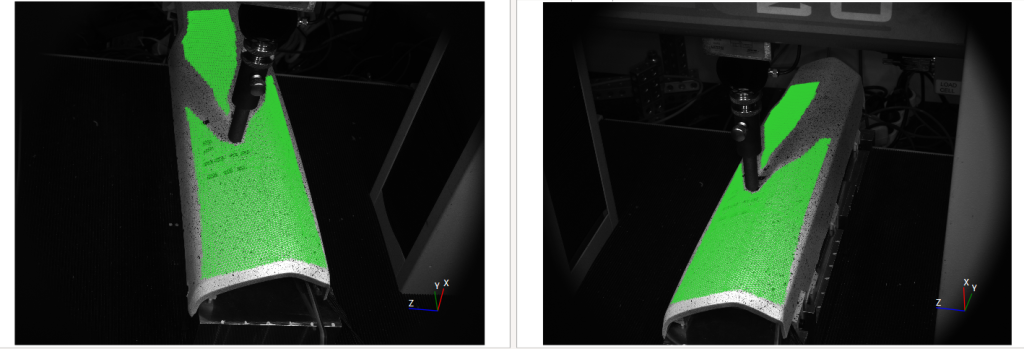

One of the specificities of this software developed by EikoSim is to use the prior knowledge of the part geometry (provided through the finite element mesh) to calibrate the camera system. This method allows us to avoid the use of calibration targets and to directly link the measurement frame to the finite element model frame.

Thus, the displacement fields will be directly expressed at the nodes of the calculation mesh. We can then directly visualize them on the images (Figure 3).

Measurement of small displacements and comparison with the simulation

Global displacement fields

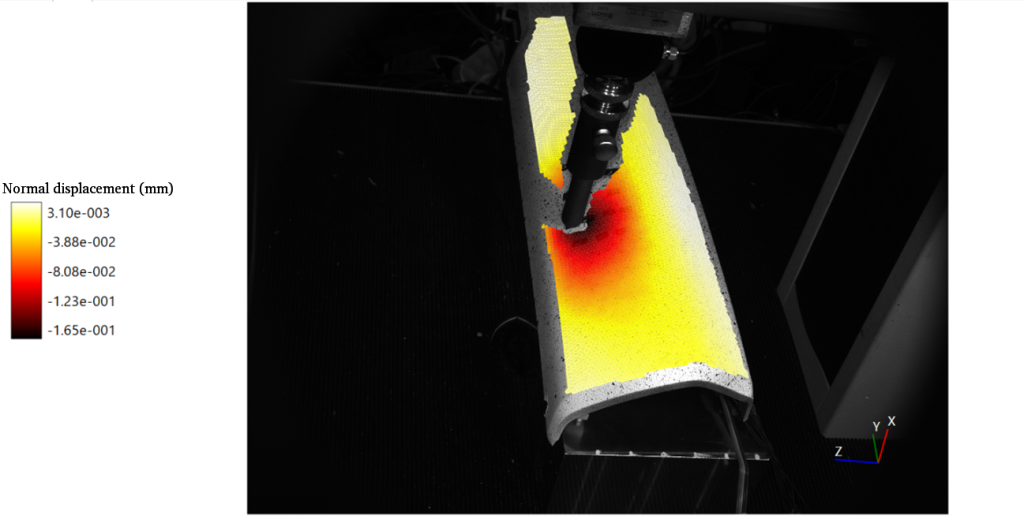

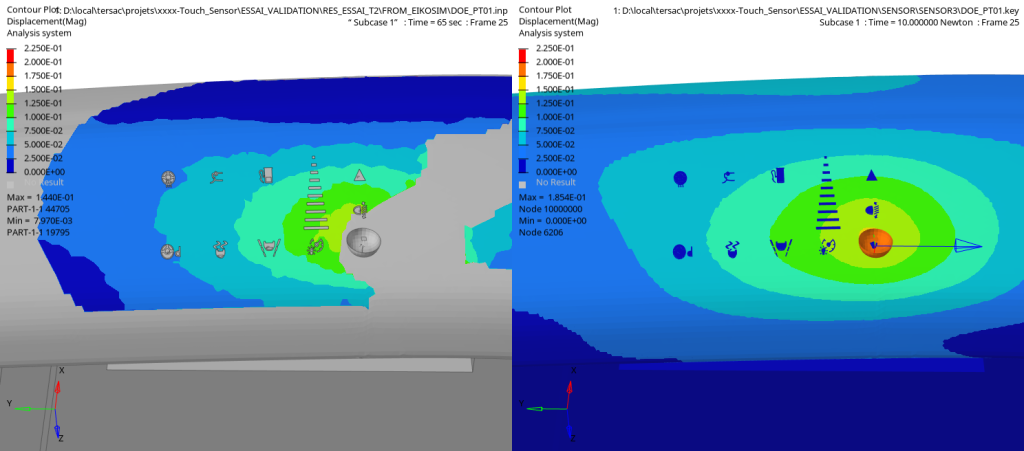

The displacements at each mesh node are measured thanks to digital image correlation. They are visible below in Figure 4 for application point 8 for a 10N load.

The maximum displacement is located just under the indentor, at the force’s application point. The normal displacement gradient observed is found for the 13 application points tested. We also notice that for the selected instrumentation, the presence of the indenter in the field of view of the pair of cameras limits the total surface on which the measurement can be carried out.

As a reminder, in order to obtain a three-dimensional displacement measurement, the texture must be observed simultaneously by at least two cameras. An improvement for a possible future campaign would be the addition of an extra camera on the other side of the indentor. This would provide 360° results around the indenter.

However, it should be noted that the information obtained through image correlation processing is much richer than that which could have been provided by strain gauges, for example, in the same configuration.

As an illustration, on the whole of the tests, the CIN provides 6000 measurements of 3D displacements for each of the images considered. The interest of the field measurement here is to allow readjusting the model over the entire area of interest. This is not the case for a finite set of point sensors.

Creation of virtual sensors

It is also possible to extract point results from the field measurement. Indeed, EikoTwin DIC allows placing virtual displacement sensors on the mesh (Figure 5). This allows us to quickly display the displacements of feature points of interest in the part over time.

The results are consistent with intuition. We observe a progressive collapse around the indentor as well as a minor collapse on the edges of the part.

Comparison of fields between tests and simulation

The main interest remains in the field comparison. This is done by exporting the results in hwascii format, in order to allow a quick comparison with the simulation results in the HyperWorks suite, used by Faurecia in this study (Figure 6).

This comparison of the experimental and simulated results fields allows us to verify that the simulation was predictive of the considered test. We verify that the application of a force produces a displacement around the point of application in the right zone.

This validates that the constitutive equation used in the finite element model to describe the behavior of the dashboard allows a very satisfactory estimation of the measured experimental field in terms of amplitude.

The shape of the field near the indentor, in particular, is very well anticipated by the calculation. Far from the indentor, on the other hand, larger deviations (but well below the measurement uncertainty) are shown.

The comparison of the results carried out directly in the reference frame of the simulation brings a second potential point of improvement. Indeed, if the points of application of the force are transferred with precision on the part by means of pads, the positioning of the part under the indentor is done manually.

This can introduce a discrepancy between the theoretical and the real point of application of the force. The processing of the experimental fields provided by the CIN allows us to find the real point of application of the force with precision.

The simulation can then be updated to apply the force as close as possible to the reality of the field. Thus, part of the uncertainty related to the application of boundary conditions in the calculation is removed as a source of error in the interpretation of the comparison. This can be automated for all the tested load application points.

Highlight of small strains

In conclusion, this study will improve the simulation of an innovative dashboard. Thanks to imaging, the EikoTwin DIC software will have succeeded in highlighting very small strains, not visible to the eye. The correlation of digital images will have made it possible to make a fast link between test data and simulation data.